TITLE 13. HOUSING

REGISTRAR'S NOTICE: The Board of Housing and Community Development is claiming an exemption from Article 2 of the Administrative Process Act pursuant to § 2.2-4006 A 12 of the Code of Virginia, which excludes regulations adopted by the Board of Housing and Community Development pursuant to the Statewide Fire Prevention Code (§ 27-94 et seq.), the Industrialized Building Safety Law (§ 36-70 et seq.), the Uniform Statewide Building Code (§ 36-97 et seq.), and § 36-98.3 of the Code of Virginia, provided the board (i) provides a Notice of Intended Regulatory Action in conformance with the provisions of § 2.2-4007.01, (ii) publishes the proposed regulation and provides an opportunity for oral and written comments as provided in § 2.2-4007.03, and (iii) conducts at least one public hearing as provided in § § 2.2-4009 and 36-100 prior to the publishing of the proposed regulations.

Title of Regulation: 13VAC5-63. Virginia Uniform Statewide Building Code (amending 13VAC5-63-10, 13VAC5-63-20, 13VAC5-63-30, 13VAC5-63-40, 13VAC5-63-50, 13VAC5-63-70, 13VAC5-63-80, 13VAC5-63-130, 13VAC5-63-150, 13VAC5-63-170, 13VAC5-63-190, 13VAC5-63-200, 13VAC5-63-210, 13VAC5-63-220, 13VAC5-63-230, 13VAC5-63-235, 13VAC5-63-240, 13VAC5-63-245, 13VAC5-63-250, 13VAC5-63-260, 13VAC5-63-264, 13VAC5-63-270, 13VAC5-63-280, 13VAC5-63-290, 13VAC5-63-295, 13VAC5-63-298, 13VAC5-63-300, 13VAC5-63-310, 13VAC5-63-320, 13VAC5-63-330, 13VAC5-63-336, 13VAC5-63-360, 13VAC5-63-370, 13VAC5-63-400, 13VAC5-63-410, 13VAC5-63-420, 13VAC5-63-430, 13VAC5-63-434, 13VAC5-63-438, 13VAC5-63-440, 13VAC5-63-443, 13VAC5-63-450, 13VAC5-63-470, 13VAC5-63-480, 13VAC5-63-490, 13VAC5-63-500, 13VAC5-63-510, 13VAC5-63-520, 13VAC5-63-530, 13VAC5-63-540; adding 13VAC5-63-268, 13VAC5-63-431, 13VAC5-63-432.5, 13VAC5-63-433, 13VAC5-63-433.3, 13VAC5-63-433.5, 13VAC5-63-434.5, 13VAC5-63-435, 13VAC5-63-435.5, 13VAC5-63-439, 13VAC5-63-441, 13VAC5-63-485, 13VAC5-63-524, 13VAC5-63-545, 13VAC5-63-549; repealing 13VAC5-63-225, 13VAC5-63-350).

Statutory Authority: § 36-98 of the Code of Virginia.

Effective Date: September 4, 2018.

Agency Contact: Elizabeth O. Rafferty, Policy and Legislative Director, Department of Housing and Community Development, Main Street Centre, 600 East Main Street, Suite 300, Richmond, VA 23219, telephone (804) 371-7011, FAX (804) 371-7090, TTY (804) 371-7089, or email elizabeth.rafferty@dhcd.virginia.gov.

Summary:

This regulatory action incorporates the newest editions of the model codes, produced by the International Code Council and other standard-writing groups, into the Virginia Uniform Statewide Building Code. The substantive changes to the Uniform Statewide Building Code (USBC) in this regulatory action are summarized as follows:

13VAC5-63-10 A and B: Updates the incorporation by reference to the latest ICC International Codes and standards.

13VAC5-63-20: Clarification of the exemption in the USBC for public utilities to include wiring and equipment of telecommunication (cellular telephone) companies. In addition, a new exemption for conveyor systems is added in subdivision D 3, as such equipment is not part of a building and therefore not within the scope of the USBC. In subdivision D 6 language is added to clarify that the demolition of manufactured homes or industrialized buildings is subject to the USBC. The prior edition of the code did not have explicit language addressing this, but demolition is a form of construction, so it did fall within the scope of the code.

13VAC5-63-30 D: Establishes a new provision for existing college research laboratories to permit compliance with special provisions in Part II of the USBC (the Virginia Existing Building Code; formerly the Virginia Rehabilitation Code) when utilizing new or differing amount of certain hazardous materials. The new provision is part of comprehensive changes to the USBC and the Statewide Fire Prevention Code (13VAC5-51) (SFPC) developed by an ad hoc committee of affected parties and representatives of educational research laboratories. The language is based on actions approved at the ICC hearings for the 2018 editions of the International Codes with conditions specific to Virginia institutions considered in the final language.

13VAC5-63-50 E and I: The Virginia Certification Standards (13VAC5-21) (VCS), also under the authority of the BHCD, were amended in September of 2014 to include requirements for continuing education and periodic training for all inspector certificates issued by the BHCD. Formerly the requirements were in the USBC, SFPC, and Virginia Amusement Device Regulations. Now that the VCS contains those requirements, duplicate requirements in the USBC are no longer necessary and are therefore being deleted.

13VAC5-63-80 B 16: A new permit exemption is added for work on billboards necessary to comply with federal guidelines of the Occupational Safety and Health Administration that is necessary so that sign companies are not subject to varying requirements from jurisdiction to jurisdiction, and safeguards are in place through the federal requirements to assure safe installations without the necessity for a USBC permit.

13VAC5-63-210 C: A new provision is added to address day treatment facilities licensed by the Virginia Department of Behavioral Health and Developmental Services to clarify that buildings used for such purposes must have sprinkler systems if located above the second story. This is necessary due to the inability of the occupants of the treatment facilities to be able to exit quickly if an emergency exists. Many occupants need assistance in evacuating due to physical or mental limitations; therefore, in sprinklered buildings, the occupants could be moved to protected areas on the floor they are on without the spread of fire to those areas since the fire would be suppressed by the sprinkler system.

13VAC5-63-210 D: An allowance is added for alcohol to be stored in wooden barrels or casks without complying with the hazardous material provisions of the code. The language was in the International Fire Code, but not in the International Building Code, as those codes are developed independently in the ICC code development process. The language is necessary to assure all breweries and producers of distilled spirits and wines are subject to consistent requirements and is based on the fact that there is no evidence that storage in wooden barrels or casks is a potential fire hazard necessitating the requirements of the code used for explosives, fireworks, flammable gases such as liquefied petroleum gas, and gasoline and diesel fuels to be applicable.

13VAC5-63-210 T 4: Adds a new exception 7 to the requirements of the International Residential Code (IRC) for separation of dwellings from lot lines to recognize zoning ordinances that require setbacks to prevent houses on adjacent lots from being within 10 feet of each other. This allows flexibility in the clustering of homes for zoning purposes and accomplishes the building code objective of maintaining fire separation distances between dwellings. The IRC requires any building wall within five feet of a property line to be of fire-rated construction without this exception.

13VAC5-63-210 T 37 and T 38: Relocates the interior passageway requirements for new homes (former subdivision T 14) and clarifies the text. Removes difficult to apply language involving doors at the end of a hallway. The overall goal of the provision is to provide doors for wheelchair users on the main level of new dwellings.

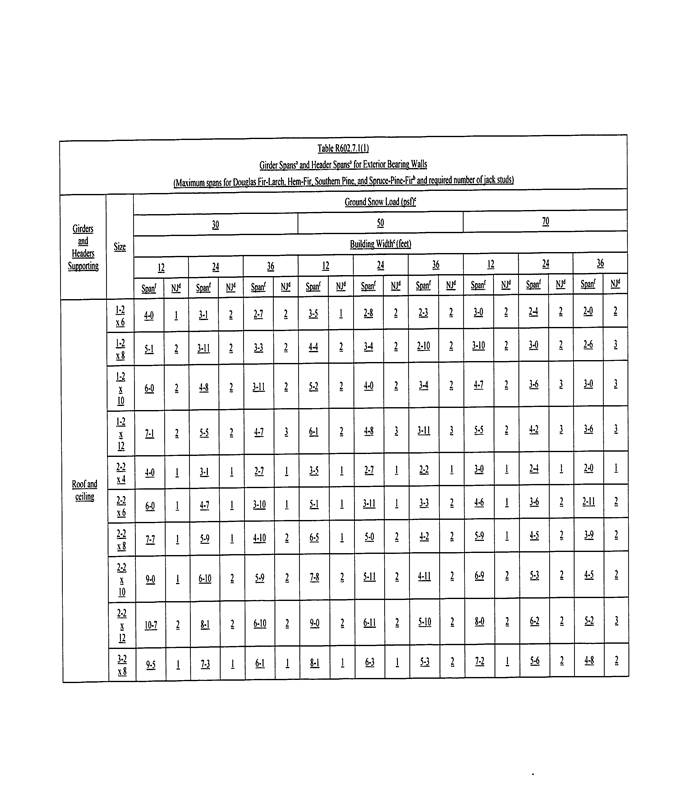

13VAC5-63-210 T 45 and T 46: Adds tables permitting the use of No. 2 (quality) southern yellow pine (wood) of appropriate spans to be used in the framing of homes. The tables in the existing regulation (2012 edition) inadvertently omitted spans for No. 2 pine and only permitted No. 1 quality, which is not readily available by wood distributors.

13VAC5-63-210 T 61: Deletes former subdivision T 94 that required only 50% of new lamps (light bulbs) to be high efficacy (efficiency) bulbs. This deletion will allow the provisions of the IRC to be applicable, which require 75% of new bulbs to be high efficiency.

13VAC5-63-210 T 69: Adds new provisions to permit the use of a corrugated gas tubing with coatings to prevent lightning arcs from causing holes in the tubing. The product has undergone the approval process through the National Fuel Gas Code and the American National Standards Institute standard writing process.

13VAC5-63-210 T 74: From a proposal submitted by the Virginia State Corporation Commission, a new provision is added to require a tracer wire to be installed in the ditch with nonmetallic water service piping to new homes. This will enable other utilities to locate the water service line when installing additional underground lines and prevent the possible inadvertent rupturing of the water service line. There was a case where a gas line crossed a water service line that was not pressurized yet and gas traveled up the water service line and caused an explosion in the house it served. Tracer wire is already required by the USBC for nonmetallic sewer lines.

13VAC5-63-220 X and Y: Establishes a new provision for new college research laboratories to utilize certain hazardous materials inherent in operations without having to fully comply with the hazardous material provisions of the code as the use of such materials is in limited quantity. The new provision is part of comprehensive changes to the USBC and the Statewide Fire Prevention Code (13VAC5-51) (SFPC) developed by an ad hoc committee of affected parties and representatives of educational research laboratories. The language is based on actions approved at the ICC hearings for the 2018 editions of the International Codes with conditions specific to Virginia institutions considered in the final language.

13VAC5-63-230 E: Reestablishes exceptions for when smoke and fire dampers are required in shaft enclosures for heating, ventilating and air-conditioning duct systems. The exceptions were in the 2009 edition of the USBC and were deleted in the 2012 edition based on wording in the 2012 International Building Code (IBC); however, since the wording in the 2012 IBC differed slightly from the 2009 USBC language, the 2009 exceptions are being reinserted.

13VAC5-63-245 L and Q: Adds language in the IBC that is consistent with the IRC stairway landing requirements when dwelling units are being designed under the IBC, such as four-story townhomes that are outside of the scope of the IRC. The same hazards exist for dwellings, whether constructed under the IBC or the IRC.

13VAC5-63-264 A 13: Deletes former subdivision A 21 that required only 50% of new lamps (light bulbs) to be high efficacy (efficiency) bulbs in buildings subject to the International Energy Conservation Code (IECC). This deletion will allow the provisions of the 2015 IECC to be applicable, which require 75% of new bulbs to be high efficiency.

13VAC5-63-295 B and C: Adds tables permitting the use of No. 2 (quality) southern yellow pine (wood) of appropriate spans to be used in the framing of dwellings constructed under the IBC. The tables in the existing regulation (2012 edition) inadvertently omitted spans for No. 2 pine and only permitted No. 1 quality, which is not readily available by wood distributors.

13VAC5-63-310 D 1, D 7, and D 8: Add requirements for pollution control units where such systems are voluntarily installed. The use of these systems to control pollutants in grease ducts in restaurants and other facilities having grease ducts has become more prevalent, and this language was approved for the 2018 International Mechanical Code (IMC) at the ICC process in time for implementing in it Virginia for the 2015 USBC.

13VAC5-63-310 D 9: Reestablishes exceptions for when smoke and fire dampers are required in shaft enclosures for heating, ventilating, and air-conditioning duct systems. The exceptions were in the 2009 edition of the USBC (in both the IBC and the IMC) and were deleted in the 2012 edition based on wording in the 2012 IMC; however, since the wording in the 2012 IMC differed slightly from the 2009 USBC language, the 2009 exceptions are being reinserted.

13VAC5-63-310 E 2 and E 5: Adds new sections to permit the use of a corrugated gas tubing with coatings to prevent lightning arcs from causing holes in the tubing in buildings subject to the IBC. The product has undergone the approval process through the National Fuel Gas Code and the American National Standards Institute standard writing process.

13VAC5-63-431 A, B, and C: Modifies the wording of the 2015 edition of the ICC International Existing Building Code (IEBC) for use in Part II of the USBC, which governs alterations, additions, and change of occupancy of existing buildings. The new wording permits an additional compliance method for alterations and repairs based on the code in effect when the building was originally constructed.

13VAC5-63-431 D: Establishes the technical requirements for a new provision for existing college research laboratories when utilizing new or differing amount of certain hazardous materials. The requirements are part of comprehensive changes to the USBC and SFPC developed by an ad hoc committee of affected parties and representatives of educational research laboratories. The language is based on actions approved at the ICC hearings for the 2018 editions of the International Codes with conditions specific to Virginia institutions considered in the final language.

13VAC5-63-422 A, B, and C: Minor changes to the 2015 IEBC to clarify the classifications of work that are covered under the Level Method of compliance in the IEBC and how the work area concept is to be applied. Clarifying language is also added for addressing buildings that have horizontal fire separation as only vertical fire separation was addressed.

13VAC5-63-433.5, 13VAC5-63-434, 13VAC5-63-434.5, 13VAC5-63-435, 13VAC5-63-439, and 13VAC5-63-440. Minor changes to the 2015 IEBC developed by an ad hoc group preparing a training module for the department's Jack A. Proctor Building Code Academy for Part II of the USBC. These changes clarify the requirements of the different compliance methods set out in the IEBC based on questions raised during the development of the training module.

Changes since publication of the proposed include:

13VAC5-63-20: Further clarifies language for power, wireless, and cable companies and adds an exemption for direct burial utility poles.

13VAC5-63-30 B: Provides that Part II of the Virginia Uniform Statewide Building Code shall be referred to as the "Virginia Existing Building Code" and shall apply to construction and rehabilitation activities in existing buildings and structures.

13VAC5-63-50 F and G: Clarifies that permit technicians are technical assistants and therefore they require the same certification mandates as other technical assistants and grandfathers any permit technician prior to the effective date of this regulation.

13VAC5-63-80 B: Adds a permit exemption to allow local jurisdictions to require a permit for exempted items located in a special flood hazard area and increases the maximum amount of roof decking replacement that can be done before a building permit is required, from 100 square feet to 256 square feet.

13VAC5-63-130 G and K: Adds the requirement for inspections for any fuel-burning appliances or equipment being replaced in existing single-family dwellings to ensure proper sizing of vent or chimney systems and to ensure that vents and chimneys are free from blockage, defects, or deterioration and are in operable condition. Allows inspection by others but requires certification to the building official that the requirements have been met. Subsection K provides that a licensed mechanical contractor may perform duct testing required by section R403.3.3 of the International Energy Conservation Code (IECC) or Section N1103.3.3 of the International Residential Code (IRC).

13VAC5-63-150 B: Provides a requirement that a notice of violation must specify a reasonable time period within which the corrections or compliance must occur and further clarifies that unsafe buildings, or structures that become unsafe during the construction process, follow a separate path of abatement under Section 118.

13VAC5-63-190 G: Changes the requirement for a decision by the local board of building code appeals to be a written decision as opposed to a resolution and adds that the decision shall be explained in writing. Throughout the appeals section replaces "resolution" with the term "written decision."

13VAC5-63-200 A and B: Adds permit technicians to the definition of "technical assistant" and changes the definition of "change of occupancy" to read "See section 202 of the VEBC" for the purpose of ensuring the term is used consistently throughout the USBC.

13VAC5-63-210 T (Changes to the IRC):

Subdivision T 12 clarifies that hazardous locations for glazing are less than 60 inches measured horizontally in a straight line from the water's edge and the bottom exposed edge of the glazing where it is less than 60 inches measured vertically above any standing or walking surface.

Subdivision T 29 adds language to clarify that a swimming pool barrier can be located on the property line and providing a prohibition for pool equipment, such as pumps, filters, and heaters, to be within three feet of the exterior of the barrier when located on the same property.

Subdivision T 44 clarifies that the intent of openings to an underfloor space is to provide cross ventilation, and when cross ventilation has been provided, openings are not required to be within three feet of each corner.

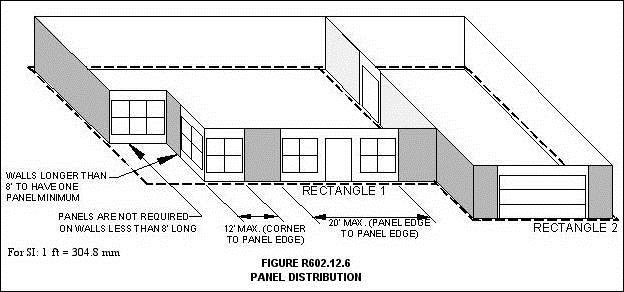

Subdivision T 51 provides requirements for braced wall panel support.

Subdivision T 53 reformats the roof construction section.

Subdivision T 60 clarifies that the REScheck compliance software developed by the U.S. Department of Energy shall be an acceptable method of determining energy code compliance.

Subdivision T 68 eliminates the visual inspection option for duct testing and requires a pressure test to be conducted and the results forwarded to the code official.

Subdivision T 70 provides an energy compliance alternative using the ERI index and provides for trade-offs when using renewable energy sources. 1

3VAC5-63-230 F: Adds a requirement for HVAC system shutdown by one of three different methods: a duct detector installed in the return duct, an area smoked detector interlocked with the HVAC equipment, or a listed heat sensor installed in the return duct.

13VAC5-63-240:

Subsection I increases the number of sprinkler heads permitted on a limited area sprinkler system from six to 20.

Subsection L eliminates a Virginia amendment on standpipes, incorporates new language for the existing pressure exemption for buildings up to 150 feet, alleviates the need for the exception regarding residual pressure, and eliminates the potential issue of pressure being waived but not volume.

Subsection T requires fire department connections to be unobstructed by fences, bushes, trees, walls, or any other fixed or moveable objects.

13VAC5-63-245:

Subsection R eliminates the requirement for ladders in limited areas to be constructed in accordance with the International Mechanical Code (IMC). This was removed due to technically infeasible and conflicting language.

Subsection W provides an exception to allow structural members supporting a roof to be penetration rated stair enclosures under certain conditions.

Subsection AA adds the use group R-4 to the list of use groups required to provide emergency escape and rescue openings.

13VAC5-63-264. (Changes to the IECC):

Subdivisions 1, 2, and 3 keep the current energy efficiency requirements related to projection factor and simple solar heat gain coefficient of windows. Adoption of the 2015 model code without amending this section would result in lower energy efficiency.

Subdivision 5 requires mechanical ventilation to be provided for Group R (residential) occupancies constructed under the IBC to ensure minimum acceptable indoor air quality in dwellings that have limited air infiltration as a result of meeting minimum energy efficiency requirements.

Subdivision 7 clarifies that the REScheck compliance software developed by the U.S. Department of Energy shall be an acceptable method of determining energy code compliance.

Subdivision 15 eliminates the visual inspection option for duct testing and requires a pressure test to be conducted and the results forwarded to the code official.

Subdivision 17 provides an energy compliance alternative using the ERI index and for trade-offs when using renewable energy sources and deletes a state amendment that established a fixed 15% fenestration area when utilizing the performance path method of energy efficiency compliance of the IECC for residential structures.

13VAC5-63-280 D: Eliminates the need to determine whether professional design is required as the basis for determining when special inspections are required for a project and, instead bases the threshold on size and height of the proposed structure.

13VAC5-63-298: Exempts one story buildings that have noncombustible exterior wall covering from complying with National Fire Protection Association 285 testing.

13VAC5-63-310 D 2 and D 4: Add minimum mechanical ventilation requirements for dwelling units in the IMC to ensure minimum acceptable indoor air quality in dwellings that have limited air infiltration as a result of meeting minimum energy efficiency requirements.

13VAC5-63-320 B 16, B 17, B 18, and B 19: Keep the current IPC storm drain sizing tables.

13VAC5-63-400 through 13VAC5-63-443: Extensively rearrange and consolidate the Virginia Rehabilitation Code to become the Virginia Existing Building Code (VEBC), provide clarification on how to apply the VEBC, and simplify scoping.

13VAC5-63-470 E: Clarifies who is responsible for the maintenance of a building, structure, system, facility, and associated equipment.

13VAC5-63-480 U: Requires manufactured home park tenants to be notified if a notice of violation is issued to an owner for violations that jeopardize park tenants' health or safety.

13VAC5-63-490: Creates a new section related to violations of the Virginia Maintenance Code and clarifies that violating the code is unlawful.

13VAC5-63-510 C: Adds definitions for applicable building code and maintains consistency with other codes.

13VAC5-63-530 D 7: Requires maintenance of nonpotable water reuse systems and provides provisions for safely abandoning a system that is no longer in use.

13VAC5-63-540 B 17: Clarifies that the owner has three options for displaying the elevator, escalator, or dumbwaiter certificate of inspection.

Part I

Construction

13VAC5-63-10. Chapter 1 Administration; Section 101 General.

A. Section 101.1 Short title. The Virginia Uniform Statewide Building Code, Part I, Construction, may be cited as the Virginia Construction Code or as the VCC. The term "USBC" shall mean the VCC unless the context in which the term is used clearly indicates it to be an abbreviation for the entire Virginia Uniform Statewide Building Code or for a different part of the Virginia Uniform Statewide Building Code.

Note: This code is also known as the 2012 2015 edition of the USBC due to the use of the 2012 2015 editions of the model codes.

B. Section 101.2 Incorporation by reference. Chapters 2 - 35 of the 2012 2015 International Building Code, published by the International Code Council, Inc., are adopted and incorporated by reference to be an enforceable part of the USBC. The term "IBC" means the 2012 2015 International Building Code, published by the International Code Council, Inc. Any codes and standards referenced in the IBC are also considered to be part of the incorporation by reference, except that such codes and standards are used only to the prescribed extent of each such reference. In addition, any provisions of the appendices of the IBC specifically identified to be part of the USBC are also considered to be part of the incorporation by reference.

Note 1: The IBC references other International Codes and standards including the following major codes:

2012 2015 International Plumbing Code (IPC)

2012 2015 International Mechanical Code (IMC)

2011 2014 NFPA 70

2012 2015 International Fuel Gas Code (IFGC)

2012 2015 International Energy Conservation Code (IECC)

2012 2015 International Residential Code (IRC)

Note 2: The IRC is applicable to the construction of detached one-family and two-family dwellings and townhouses as set out in Section 310.

C. Section 101.3 Numbering system. A dual numbering system is used in the USBC to correlate the numbering system of the Virginia Administrative Code with the numbering system of the IBC. IBC numbering system designations are provided in the catchlines of the Virginia Administrative Code sections. Cross references between sections or chapters of the USBC use only the IBC numbering system designations. The term "chapter" is used in the context of the numbering system of the IBC and may mean a chapter in the USBC, a chapter in the IBC or a chapter in a referenced code or standard, depending on the context of the use of the term. The term "chapter" is not used to designate a chapter of the Virginia Administrative Code, unless clearly indicated.

D. Section 101.4 Arrangement of code provisions. The USBC is comprised of the combination of (i) the provisions of Chapter 1, Administration, which are established herein, (ii) Chapters 2 - 35 of the IBC, which are incorporated by reference in Section 101.2, and (iii) the changes to the text of the incorporated chapters of the IBC that are specifically identified. The terminology "changes to the text of the incorporated chapters of the IBC that are specifically identified" shall also be referred to as the "state amendments to the IBC." Such state amendments to the IBC are set out using corresponding chapter and section numbers of the IBC numbering system. In addition, since Chapter 1 of the IBC is not incorporated as part of the USBC, any reference to a provision of Chapter 1 of the IBC in the provisions of Chapters 2 - 35 of the IBC is generally invalid. However, where the purpose of such a reference would clearly correspond to a provision of Chapter 1 established herein, then the reference may be construed to be a valid reference to such corresponding Chapter 1 provision.

E. Section 101.5 Use of terminology and notes. The provisions of this code shall be used as follows:

1. The term "this code," or "the code," where used in the provisions of Chapter 1, in Chapters 2 - 35 of the IBC or in the state amendments to the IBC means the USBC, unless the context clearly indicates otherwise.

2. The term "this code" or "the code" where used in a code or standard referenced in the IBC means that code or standard, unless the context clearly indicates otherwise.

3. The use of notes in Chapter 1 is to provide information only and shall not be construed as changing the meaning of any code provision.

4. Notes in the IBC, in the codes and standards referenced in the IBC and in the state amendments to the IBC may modify the content of a related provision and shall be considered to be a valid part of the provision, unless the context clearly indicates otherwise.

F. Section 101.6 Order of precedence. The provisions of this code shall be used as follows:

1. The provisions of Chapter 1 of this code supersede any provisions of Chapters 2 - 35 of the IBC that address the same subject matter and impose differing requirements.

2. The provisions of Chapter 1 of this code supersede any provisions of the codes and standards referenced in the IBC that address the same subject matter and impose differing requirements.

3. The state amendments to the IBC supersede any provisions of Chapters 2 - 35 of the IBC that address the same subject matter and impose differing requirements.

4. The state amendments to the IBC supersede any provisions of the codes and standards referenced in the IBC that address the same subject matter and impose differing requirements.

5. The provisions of Chapters 2 - 35 of the IBC supersede any provisions of the codes and standards referenced in the IBC that address the same subject matter and impose differing requirements.

G. Section 101.7 Administrative provisions. The provisions of Chapter 1 establish administrative requirements, which include but are not limited to provisions relating to the scope of the code, enforcement, fees, permits, inspections and disputes. Any provisions of Chapters 2 - 35 of the IBC or any provisions of the codes and standards referenced in the IBC that address the same subject matter and impose differing requirements are deleted and replaced by the provisions of Chapter 1. Further, any administrative requirements contained in the state amendments to the IBC shall be given the same precedence as the provisions of Chapter 1. Notwithstanding the above, where administrative requirements of Chapters 2 - 35 of the IBC or of the codes and standards referenced in the IBC are specifically identified as valid administrative requirements in Chapter 1 of this code or in the state amendments to the IBC, then such requirements are not deleted and replaced.

Note: The purpose of this provision is to eliminate overlap, conflicts and duplication by providing a single standard for administrative, procedural and enforcement requirements of this code.

H. Section 101.8 Definitions. The definitions of terms used in this code are contained in Chapter 2 along with specific provisions addressing the use of definitions. Terms may be defined in other chapters or provisions of the code and such definitions are also valid.

Note: The order of precedence outlined in Section 101.6 may be determinative in establishing how to apply the definitions in the IBC and in the referenced codes and standards.

13VAC5-63-20. Section 102 Purpose and scope.

A. Section 102.1 Purpose. In accordance with § 36-99 of the Code of Virginia, the purpose of the USBC is to protect the health, safety and welfare of the residents of the Commonwealth of Virginia, provided that buildings and structures should be permitted to be constructed at the least possible cost consistent with recognized standards of health, safety, energy conservation and water conservation, including provisions necessary to prevent overcrowding, rodent or insect infestation, and garbage accumulation; and barrier-free provisions for the physically handicapped and aged.

B. Section 102.2 Scope. This section establishes the scope of the USBC in accordance with § 36-98 of the Code of Virginia. The USBC shall supersede the building codes and regulations of the counties, municipalities and other political subdivisions and state agencies. This code also shall supersede the provisions of local ordinances applicable to single-family residential construction that (i) regulate dwelling foundations or crawl spaces, (ii) require the use of specific building materials or finishes in construction, or (iii) require minimum surface area or numbers of windows; however, this code shall not supersede proffered conditions accepted as a part of a rezoning application, conditions imposed upon the grant of special exceptions, special or conditional use permits or variances, conditions imposed upon a clustering of single-family homes and preservation of open space development through standards, conditions, and criteria established by a locality pursuant to subdivision 8 of § 15.2-2242 of the Code of Virginia or subdivision A 12 of § 15.2-2286 § 15.2-2286.1 of the Code of Virginia, or land use requirements in airport or highway overlay districts, or historic districts created pursuant to § 15.2-2306 of the Code of Virginia, or local flood plain regulations adopted as a condition of participation in the National Flood Insurance Program.

Note: Requirements relating to functional design are contained in Section 103.10 of this code.

C. Section 102.2.1 Invalidity of provisions. To the extent that any provisions of this code are in conflict with Chapter 6 (§ 36-97 et seq.) of Title 36 of the Code of Virginia or in conflict with the scope of the USBC, those provisions are considered to be invalid to the extent of such conflict.

D. Section 102.3 Exemptions. The following are exempt from this code:

1. Equipment [ , ] related [ and ] wiring [ , and ] poles and towers [ supporting ] the related [ structures ] used for providing [ wired ] utility, [ telecommunications communications ], information, [ or ] cable television [ , broadcast or radio ] service in accordance with all of the following conditions:

[ 1.1. The equipment, wiring ] installed [ , and supporting structures are owned and controlled by a provider of publicly regulated utility service or a franchised cable television operator ] and electrical [ or its affiliates.

1.2. 1.1. ] The equipment and related [ , and ] wiring used for radio, broadcast or cable television, telecommunications or information service transmission. The exemption shall apply only if under applicable federal and state law the ownership and control of the equipment and wiring is by the service provider or its affiliates. Such exempt equipment and wiring shall be [ , and supporting structures ] are located on either rights-of-way or property for which the service provider has rights of occupancy and entry; however, the structures, including their service equipment,.

[ 1.3. 1.2. ] Buildings housing or supporting such exempt equipment and wiring shall be subject to the USBC.

[ 1.4. 1.3. ] The installation of equipment and [ , and ] wiring [ , and supporting structures ] exempted by this section shall not create an unsafe condition prohibited by the USBC.

2. [ Support structures owned or controlled by a provider of publicly regulated utility service or its affiliates for the transmission and distribution of electric service in accordance with all of the following conditions:

2.1. The support structures are located on either rights-of-way or property for which the service provider has rights of occupancy and entry.

2.2. The support structures exempted by this section shall not create an unsafe condition prohibited by the USBC.

3. Direct burial poles used to support equipment or wiring providing communications, information or cable television services. The poles exempted by this section shall not create an unsafe condition prohibited by the USBC.

4. ] Electrical equipment, transmission equipment, and related wiring used for wireless transmission of radio, broadcast, telecommunications, or information service in accordance with all of the following conditions:

[ 2.1. 4.1. ] Buildings housing exempt equipment and wiring and structures supporting exempt equipment and wiring shall be subject to the USBC.

[ 2.2. 4.2. ] The equipment and wiring exempted by this section shall not create an unsafe condition prohibited by the USBC.

2. [ 3. 5. ] Manufacturing and, processing, and product handling machines and equipment that do not produce or process hazardous materials regulated by this code, including those portions of conveyor systems used exclusively for the transport of associated materials or products, and all of the following service equipment associated with the manufacturing or processing machines.:

2.1. [ 3.1. 5.1. ] Electrical equipment connected after the last disconnecting means.

2.2. [ 3.2. 5.2. ] Plumbing piping and equipment connected after the last shutoff valve or backflow device and before the equipment drain trap.

2.3. [ 3.3. 5.3. ] Gas piping and equipment connected after the outlet shutoff valve.

Manufacturing and processing machines that produce or process hazardous materials regulated by this code are only required to comply with the code provisions regulating the hazardous materials.

3. [ 4. 6. ] Parking lots and sidewalks that are not part of an accessible route.

4. [ 5. 7. ] Nonmechanized playground or recreational equipment such as swing sets, sliding boards, climbing bars, jungle gyms, skateboard ramps, and similar equipment where no admission fee is charged for its use or for admittance to areas where the equipment is located.

5. [ 6. 8. ] Industrialized buildings subject to the Virginia Industrialized Building Safety Regulations (13VAC5-91) and manufactured homes subject to the Virginia Manufactured Home Safety Regulations (13VAC5-95); except as provided for in Section 425 427 and in the case of demolition of such industrialized buildings or manufactured homes.

6. [ 7. 9. ] Farm buildings and structures, except for a building or a portion of a building located on a farm that is operated as a restaurant as defined in § 35.1-1 of the Code of Virginia and licensed as such by the Virginia Board of Health pursuant to Chapter 2 (§ 35.1-11 et seq.) of Title 35.1 of the Code of Virginia. However, farm buildings and structures lying within a flood plain or in a mudslide-prone area shall be subject to flood-proofing regulations or mudslide regulations, as applicable.

7. [ 8. 10. ] Federally owned buildings and structures unless federal law specifically requires a permit from the locality. Underground storage tank installations, modifications and removals shall comply with this code in accordance with federal law.

8. [ 9. 11. ] Off-site manufactured intermodal freight containers, moving containers, and storage containers placed on site temporarily or permanently for use as a storage container.

9. [ 10. 12. ] Automotive lifts.

13VAC5-63-30. Section 103 Application of code.

A. Section 103.1 General. In accordance with § 36-99 of the Code of Virginia, the USBC shall prescribe building regulations to be complied with in the construction and rehabilitation of buildings and structures, and the equipment therein.

B. [ Section 103.1.1 Virginia Existing Building Code. Part II of the Virginia Uniform Statewide Building Code, also known as the "Virginia Existing Building Code," or the "VEBC" is applicable to construction and rehabilitation activities in existing buildings and structures, as those terms are defined in the VEBC, except where specifically addressed in the VCC.

C. ] Section 103.2 When applicable to new construction. Construction for which a permit application is submitted to the local building department on or after the effective date of the 2012 2015 edition of the code shall comply with the provisions of this code, except for permit applications submitted during a one-year period beginning on the effective date of the 2012 2015 edition of the code. The applicant for a permit during such one-year period shall be permitted to choose whether to comply with the provisions of this code or the provisions of the edition of the code in effect immediately prior to the 2012 2015 edition. This provision shall also apply to subsequent amendments to this code based on the effective date of such amendments. In addition, when a permit has been properly issued under a previous edition of this code, this code shall not require changes to the approved construction documents, design or construction of such a building or structure, provided the permit has not been suspended or revoked.

[ C. Section 103.3 Change of occupancy. No change of occupancy shall be made in any structure when the current USBC requires a greater degree of accessibility, structural strength, fire protection, means of egress, ventilation or sanitation. When such a greater degree is required, the owner or the owner's agent shall comply with the following:

1. When involving Group I-2 or I-3, written application shall be made to the local building department for a new certificate of occupancy and the new certificate of occupancy shall be obtained prior to the new use of the structure. When impractical to achieve compliance with this code for the new occupancy classification, the building official shall consider modifications upon application and as provided for in Section 106.3. In addition, the applicable accessibility provisions of Section 1012.8 of Part II of the Virginia Uniform Statewide Building Code, also known as the "Virginia ] Rehabilitation [ Existing Building Code," or the ] "VRC" [ "VEBC" shall be met.

Exception: This section shall not be construed to permit noncompliance with any applicable flood load or flood-resistant construction requirements of this code.

2. In other than Group I-2 or I-3, the provisions of the ] VRC [ VEBC for change of occupancy shall be met.

D. Section 103.3.1 Group B teaching and research laboratories. Where the use of new or different hazardous materials or a change in the amount of hazardous materials in existing Group B teaching and research laboratories in educational occupancies above the 12th grade would constitute a change of occupancy, Section 302.6 of the VEBC shall be permitted to be used as an acceptable alternative to compliance with change of occupancy requirements to permit the increased amounts of hazardous materials stipulated without the laboratories being classified as Group H.

E. Section 103.4 Additions. Additions to buildings and structures shall comply with the requirements of this code for new construction or shall comply with the ] VRC [ VEBC. An existing building or structure plus additions shall comply with the height and area provisions of Chapter 5 and the applicable provisions of Chapter 9. Further, this code shall not require changes to the design or construction of any portions of the building or structure not altered or affected by an addition, unless the addition has the effect of lowering the current level of safety.

Exceptions:

1. This section shall not be construed to permit noncompliance with any applicable flood load or flood-resistant construction requirements of this code.

2. When this code is used for compliance, existing structural elements carrying gravity loads shall be permitted to comply with Section 1103 of the ] International Existing Building Code [ VEBC. ]

E. [ F. Section 103.5 Reconstruction, alteration or repair in Group R-5 occupancies. The following criteria is applicable to reconstruction, alteration or repair of Group R-5 buildings or structures:

1. Any reconstruction, alteration or repair shall not adversely affect the performance of the building or structure, or cause the building or structure to become unsafe or lower existing levels of health and safety.

2. Parts of the building or structure not being reconstructed, altered or repaired shall not be required to comply with the requirements of this code applicable to newly constructed buildings or structures.

3. The installation of material or equipment, or both, that is neither required nor prohibited shall only be required to comply with the provisions of this code relating to the safe installation of such material or equipment.

4. Material or equipment, or both, may be replaced in the same location with material or equipment of a similar kind or capacity.

Exceptions:

1. This section shall not be construed to permit noncompliance with any applicable flood load or flood-resistant construction requirements of this code.

2. Reconstructed decks, balconies, porches and similar structures located 30 inches (762 mm) or more above grade shall meet the current code provisions for structural loading capacity, connections and structural attachment. This requirement excludes the configuration and height of handrails and guardrails.

3. Compliance with the ] VRC [ VEBC shall be an acceptable alternative to compliance with this section at the discretion of the owner or owner's agent. ]

F. [ G. Section 103.5.1 Equipment changes. Upon the replacement or new installation of any fuel-burning appliances or equipment in existing Group R-5 occupancies, an inspection or inspections shall be conducted to ensure that the connected vent or chimney systems comply with the following:

1. Vent or chimney systems are sized in accordance with the IRC.

2. Vent or chimney systems are clean, free of any obstruction or blockages, defects, or deterioration, and are in operable condition. Where not inspected by the local building department, persons performing such changes or installations shall certify to the building official that the requirements of Items 1 and 2 of this section are met. ]

G. [ H. Section 103.6 Reconstruction, alteration, and repair in other occupancies. Reconstruction, alteration, and repair in occupancies other than Group R-5 shall comply with the ] VRC [ VEBC. ]

H. [ I. Section 103.7 Retrofit requirements. The local building department shall enforce the provisions of Section 1701 of the ] VRC, which require certain existing buildings to be retrofitted with fire protection systems and other safety equipment. Retroactive fire protection system requirements contained in the International Fire Code (IFC) shall not be applicable unless required for compliance with the provisions of Section 1701 of the VRC [ VEBC. ]

I. [ J. D. ] Section [ 103.8 103.3 ] Nonrequired equipment. The following criteria for nonrequired equipment is in accordance with § 36-103 of the Code of Virginia. Building owners may elect to install partial or full fire alarms or other safety equipment that was not required by the edition of the USBC in effect at the time a building was constructed without meeting current requirements of the code, provided the installation does not create a hazardous condition. Permits for installation shall be obtained in accordance with this code. In addition, as a requirement of this code, when such nonrequired equipment is to be installed, the building official shall notify the appropriate fire official or fire chief.

J. [ K. E. ] Section [ 103.8.1 103.3.1 ] Reduction in function or discontinuance of nonrequired fire protection systems. When a nonrequired fire protection system is to be reduced in function or discontinued, it shall be done in such a manner so as not to create a false sense of protection. Generally, in such cases, any features visible from interior areas shall be removed, such as sprinkler heads, smoke detectors or alarm panels or devices, but any wiring or piping hidden within the construction of the building may remain. Approval of the proposed method of reduction or discontinuance shall be obtained from the building official.

K. [ L. F. ] Section [ 103.9 103.4 ] Use of certain provisions of referenced codes. The following provisions of the IBC and of other indicated codes or standards are to be considered valid provisions of this code. Where any such provisions have been modified by the state amendments to the IBC, then the modified provisions apply.

1. Special inspection requirements in Chapters 2 - 35.

2. Testing requirements and requirements for the submittal of construction documents in any of the ICC codes referenced in Chapter 35 and in the IRC.

3. Section R301.2 of the IRC authorizing localities to determine climatic and geographic design criteria.

4. Flood load or flood-resistant construction requirements in the IBC or the IRC, including, but not limited to, any such provisions pertaining to flood elevation certificates that are located in Chapter 1 of those codes. Any required flood elevation certificate pursuant to such provisions shall be prepared by a land surveyor licensed in Virginia or an RDP.

5. Section R101.2 of the IRC.

6. Section N1101.6 N1102.1 of the IRC and Sections C101.5.2 C402.1.1 and R101.5.2 R402.1 of the IECC.

L. [ M. G. ] Section [ 103.10 103.5 ] Functional design. The following criteria for functional design is in accordance with § 36-98 of the Code of Virginia. The USBC shall not supersede the regulations of other state agencies that require and govern the functional design and operation of building related activities not covered by the USBC, including but not limited to (i) public water supply systems, (ii) waste water treatment and disposal systems, and (iii) solid waste facilities. Nor shall state agencies be prohibited from requiring, pursuant to other state law, that buildings and equipment be maintained in accordance with provisions of this code. In addition, as established by this code, the building official may refuse to issue a permit until the applicant has supplied certificates of functional design approval from the appropriate state agency or agencies. For purposes of coordination, the locality may require reports to the building official by other departments or agencies indicating compliance with their regulations applicable to the functional design of a building or structure as a condition for issuance of a building permit or certificate of occupancy. Such reports shall be based upon review of the plans or inspection of the project as determined by the locality. All enforcement of these conditions shall not be the responsibility of the building official, but rather the agency imposing the condition.

Note: Identified state agencies with functional design approval are listed in the "Related Laws Package," which is available from DHCD.

M. [ N. H. ] Section [ 103.11 103.6 ] Amusement devices and inspections. In accordance with § 36-98.3 of the Code of Virginia, to the extent they are not superseded by the provisions of § 36-98.3 of the Code of Virginia and the VADR, the provisions of the USBC shall apply to amusement devices. In addition, as a requirement of this code, inspections for compliance with the VADR shall be conducted either by local building department personnel or private inspectors provided such persons are certified as amusement device inspectors under the VCS.

N. [ O. I. ] Section [ 103.12 103.7 ] State buildings and structures. This section establishes the application of the USBC to state-owned buildings and structures in accordance with § 36-98.1 of the Code of Virginia. The USBC shall be applicable to all state-owned buildings and structures, with the exception that §§ 2.2-1159 through 2.2-1161 of the Code of Virginia shall provide the standards for ready access to and use of state-owned buildings by the physically handicapped.

Any state-owned building or structure or building built on state-owned property for which preliminary plans were prepared or on which construction commenced after the initial effective date of the USBC, shall remain subject to the provisions of the USBC that were in effect at the time such plans were completed or such construction commenced. Subsequent reconstruction, renovation or demolition of such building or structure shall be subject to the pertinent provisions of this code.

Acting through the Division of Engineering and Buildings, the Virginia Department of General Services shall function as the building official for state-owned buildings. The department shall review and approve plans and specifications, grant modifications, and establish such rules and regulations as may be necessary to implement this section. It shall provide for the inspection of state-owned buildings and enforcement of the USBC and standards for access by the physically handicapped by delegating inspection and USBC enforcement duties to the State Fire Marshal's Office, to other appropriate state agencies having needed expertise, and to local building departments, all of which shall provide such assistance within a reasonable time and in the manner requested. State agencies and institutions occupying buildings shall pay to the local building department the same fees as would be paid by a private citizen for the services rendered when such services are requested by the department. The department may alter or overrule any decision of the local building department after having first considered the local building department's report or other rationale given for its decision. When altering or overruling any decision of a local building department, the department shall provide the local building department with a written summary of its reasons for doing so.

Notwithstanding any provision of this code to the contrary, roadway tunnels and bridges owned by the Virginia Department of Transportation shall be exempt from this code. The Virginia Department of General Services shall not have jurisdiction over such roadway tunnels, bridges and other limited access highways; provided, however, that the Department of General Services shall have jurisdiction over any occupied buildings within any Department of Transportation rights-of-way that are subject to this code.

Except as provided in subsection D E of § 23-38.109 23.1-1016 of the Code of Virginia, and notwithstanding any provision of this code to the contrary, at the request of a public institution of higher education, the Virginia Department of General Services, as further set forth in this provision, shall authorize that institution of higher education to contract with a building official of the locality in which the construction is taking place to perform any inspection and certifications required for the purpose of complying with this code. The department shall publish administrative procedures that shall be followed in contracting with a building official of the locality. The authority granted to a public institution of higher education under this provision to contract with a building official of the locality shall be subject to the institution meeting the conditions prescribed in subsection B A of § 23-38.88 23.1-1002 of the Code of Virginia.

Note: In accordance with § 36-98.1 of the Code of Virginia, roadway tunnels and bridges shall be designed, constructed and operated to comply with fire safety standards based on nationally recognized model codes and standards to be developed by the Virginia Department of Transportation in consultation with the State Fire Marshal and approved by the Virginia Commonwealth Transportation Board. Emergency response planning and activities related to the standards approved by the Commonwealth Transportation Board shall be developed by the Department of Transportation and coordinated with the appropriate local officials and emergency service providers. On an annual basis, the Department of Transportation shall provide a report on the maintenance and operability of installed fire protection and detection systems in roadway tunnels and bridges to the State Fire Marshal.

O. [ P. J. ] Section [ 103.12.1 103.7.1 ] Certification of state enforcement personnel. State enforcement personnel shall comply with the applicable requirements of Section 105 for certification, periodic maintenance training, and continuing education.

13VAC5-63-40. Section 104 Enforcement, generally.

A. Section 104.1 Scope of enforcement. This section establishes the requirements for enforcement of the USBC in accordance with § 36-105 of the Code of Virginia. Enforcement of the provisions of the USBC for construction and rehabilitation shall be the responsibility of the local building department. Whenever a county or municipality does not have such a building department, the local governing body shall enter into an agreement with the local governing body of another county or municipality or with some other agency, or a state agency approved by DHCD for such enforcement. For the purposes of this section, towns with a population of less than 3,500 may elect to administer and enforce the USBC; however, where the town does not elect to administer and enforce the code, the county in which the town is situated shall administer and enforce the code for the town. In the event such town is situated in two or more counties, those counties shall administer and enforce the USBC for that portion of the town situated within their respective boundaries.

However, upon a finding by the local building department, following a complaint by a tenant of a residential dwelling unit that is the subject of such complaint, that there may be a violation of the unsafe structures provisions of Part III of the Virginia Uniform Statewide Building Code, also known as the "Virginia Maintenance Code," or the "VMC," the local building department shall enforce such provisions.

If the local building department receives a complaint that a violation of the VMC exists that is an immediate and imminent threat to the health or safety of the owner, tenant, or occupants of any building or structure, or the owner, occupant, or tenant of any nearby building or structure, and the owner, occupant, or tenant of the building or structure that is the subject of the complaint has refused to allow the local building official or his agent to have access to the subject building or structure, the local building official or his agent may present sworn testimony to make an affidavit under oath before a magistrate or a court of competent jurisdiction and request that the magistrate or court grant the local building official or his agent an inspection warrant to enable the building official or his agent to enter the subject building or structure for the purpose of determining whether violations of the VMC exist. After issuing a warrant under this section, the magistrate or judge shall file the affidavit in the manner prescribed by § 19.2-54 of the Code of Virginia. After executing the warrant, the local building official or his agents shall return the warrant to the clerk of the circuit court of the city or county wherein the inspection was made. The local building official or his agent shall make a reasonable effort to obtain consent from the owner, occupant, or tenant of the subject building or structure prior to seeking the issuance of an inspection warrant under this section.

The local governing body shall, however, inspect and enforce the provisions of the VMC for elevators, escalators, and related conveyances, except for elevators in single-family and two-family homes and townhouses. Such inspection and enforcement shall be carried out by an agency or department designated by the local governing body.

B. Section 104.2 Interagency coordination. When any inspection functions under this code are assigned to a local agency other than the local building department, such agency shall coordinate its reports of inspection with the local building department.

13VAC5-63-50. Section 105 Local building department.

A. Section 105.1 Appointment of building official. Every local building department shall have a building official as the executive official in charge of the department. The building official shall be appointed in a manner selected by the local governing body. After permanent appointment, the building official shall not be removed from office except for cause after having been afforded a full opportunity to be heard on specific and relevant charges by and before the appointing authority. DHCD shall be notified by the appointing authority within 30 days of the appointment or release of a permanent or acting building official.

Note: Building officials are subject to sanctions in accordance with the VCS.

B. Section 105.1.1 Qualifications of building official. The building official shall have at least five years of building experience as a licensed professional engineer or architect, building, fire or trade inspector, contractor, housing inspector or superintendent of building, fire or trade construction or at least five years of building experience after obtaining a degree in architecture or engineering, with at least three years in responsible charge of work. Any combination of education and experience that would confer equivalent knowledge and ability shall be deemed to satisfy this requirement. The building official shall have general knowledge of sound engineering practice in respect to the design and construction of structures, the basic principles of fire prevention, the accepted requirements for means of egress and the installation of elevators and other service equipment necessary for the health, safety and general welfare of the occupants and the public. The local governing body may establish additional qualification requirements.

C. Section 105.1.2 Certification of building official. An acting or permanent building official shall be certified as a building official in accordance with the VCS within one year after being appointed as acting or permanent building official.

Exception: A building official in place prior to April 1, 1983, shall not be required to meet the certification requirements in this section while continuing to serve in the same capacity in the same locality.

D. Section 105.1.3 Noncertified building official. Except for a building official exempt from certification under the exception to Section 105.1.2, any acting or permanent building official who is not certified as a building official in accordance with the VCS shall attend the core module of the Virginia Building Code Academy or an equivalent course in an individual or regional code academy accredited by DHCD within 180 days of appointment. This requirement is in addition to meeting the certification requirement in Section 105.1.2.

E. Section 105.1.4 Requirements for periodic maintenance and continuing education. Building officials shall attend periodic maintenance training as designated by DHCD. In addition to the periodic maintenance training required above, building officials shall attend 16 hours of continuing education every two years as approved by DHCD. If a building official possesses more than one BHCD certificate, the 16 hours shall satisfy the continuing education requirement for all BHCD certificates.

Note: Continuing education and periodic training requirements for DHCD certifications are set out in the VCS.

F. E. Section 105.2 Technical assistants. The building official, subject to any limitations imposed by the locality, shall be permitted to utilize technical assistants to assist the building official in the enforcement of the USBC. DHCD shall be notified by the building official within 60 days of the employment of, contracting with or termination of all technical assistants.

Note: Technical assistants are subject to sanctions in accordance with the VCS.

G. F. Section 105.2.1 Qualifications of technical assistants. A technical assistant shall have at least three years of experience and general knowledge in at least one of the following areas: building construction; [ building construction conceptual and administrative processes; ] building, fire or housing inspections; plumbing, electrical or mechanical trades; or fire protection, elevator or property maintenance work. Any combination of education and experience that would confer equivalent knowledge and ability shall be deemed to satisfy this requirement. The locality may establish additional qualification requirements.

H. G. Section 105.2.2 Certification of technical assistants. A technical assistant shall be certified in the appropriate subject area within 18 months after becoming a technical assistant. When required by local policy to have two or more certifications, a technical assistant shall obtain the additional certifications within three years from the date of such requirement.

[ Exception Exceptions:

1. ] A technical assistant in place prior to March 1, 1988, shall not be required to meet the certification requirements in this section while continuing to serve in the same capacity in the same locality.

[ 2. A permit technician in place prior to the effective date of the 2015 edition of the code shall not be required to meet the certification requirements in this section while continuing to serve in the same capacity in the same locality. ]

I. Section 105.2.3 Requirements for periodic maintenance and continuing education. Technical assistants shall attend periodic maintenance training as designated by DHCD. In addition to the periodic maintenance training required above, technical assistants shall attend 16 hours of continuing education every two years as approved by DHCD. If a technical assistant possesses more than one BHCD certificate, the 16 hours shall satisfy the continuing education requirement for all BHCD certificates.

Note: Continuing education and periodic training requirements for DHCD certifications are set out in the VCS.

J. H. Section 105.3 Conflict of interest. The standards of conduct for building officials and technical assistants shall be in accordance with the provisions of the State and Local Government Conflict of Interests Act, Chapter 31 (§ 2.2-3100 et seq.) of Title 2.2 of the Code of Virginia.

K. I. Section 105.4 Records. The local building department shall retain a record of applications received, permits, certificates, notices and orders issued, fees collected and reports of inspection in accordance with The Library of Virginia's General Schedule Number Six.

13VAC5-63-70. Section 107 Fees.

A. Section 107.1 Authority for charging fees. In accordance with § 36-105 of the Code of Virginia, fees may be levied by the local governing body in order to defray the cost of enforcement of the USBC.

Note: See subsection D of § 36-105 of the Code of Virginia for rules for permit fees involving property with easements or liens.

B. Section 107.1.1 Fee schedule. The local governing body shall establish a fee schedule incorporating unit rates, which may be based on square footage, cubic footage, estimated cost of construction or other appropriate criteria. A permit or any amendments to an existing permit shall not be issued until the designated fees have been paid, except that the building official may authorize the delayed payment of fees.

C. Section 107.1.2 Refunds. When requested in writing by a permit holder, the locality shall provide a fee refund in the case of the revocation of a permit or the abandonment or discontinuance of a building project. The refund shall not be required to exceed an amount which correlates to work not completed.

D. Section 107.1.3 Fees for generators used with amusement devices. Fees for generators and associated wiring used with amusement devices shall only be charged under the Virginia Amusement Device Regulations (13VAC5-31).

E. Section 107.2 Code academy fee levy. In accordance with subdivision 7 of § 36-137 of the Code of Virginia, the local building department shall collect a 2.0% levy of fees charged for permits issued under this code and transmit it quarterly to DHCD to support training programs of the Virginia Building Code Academy. Localities that maintain individual or regional training academies accredited by DHCD shall retain such levy.

13VAC5-63-80. Section 108 Application for permit.

A. Section 108.1 When applications are required. Application for a permit shall be made to the building official and a permit shall be obtained prior to the commencement of any of the following activities, except that applications for emergency construction, alterations or equipment replacement shall be submitted by the end of the first working day that follows the day such work commences. In addition, the building official may authorize work to commence pending the receipt of an application or the issuance of a permit.

1. Construction or demolition of a building or structure. Installations or alterations involving (i) the removal or addition of any wall, partition or portion thereof, (ii) any structural component, (iii) the repair or replacement of any required component of a fire or smoke rated assembly, (iv) the alteration of any required means of egress system, (v) water supply and distribution system, sanitary drainage system or vent system, (vi) electric wiring, (vii) fire protection system, mechanical systems, or fuel supply systems, or (viii) any equipment regulated by the USBC.

2. For change of occupancy, application for a permit shall be made when a new certificate of occupancy is required [ under Section 103.3 by the VEBC ].

3. Movement of a lot line that increases the hazard to or decreases the level of safety of an existing building or structure in comparison to the building code under which such building or structure was constructed.

4. Removal or disturbing of any asbestos containing materials during the construction or demolition of a building or structure, including additions.

B. Section 108.2 Exemptions from application for permit. Notwithstanding the requirements of Section 108.1, application for a permit and any related inspections shall not be required for the following; however, this section shall not be construed to exempt such activities from other applicable requirements of this code. In addition, when an owner or an owner's agent requests that a permit be issued for any of the following, then a permit shall be issued and any related inspections shall be required.

1. Installation of wiring and equipment that (i) operates at less than 50 volts, (ii) is for [ network powered ] broadband communications systems, [ or ] (iii) is exempt under Section 102.3(1) or [ 102.3(2) 102.3(4) ], [ or (iv) is for monitoring or automation systems in dwelling units, ] except when any such installations are located in a plenum, penetrate fire rated or smoke protected construction or are a component of any of the following:

1.1. Fire alarm system.

1.2. Fire detection system.

1.3. Fire suppression system.

1.4. Smoke control system.

1.5. Fire protection supervisory system.

1.6. Elevator fire safety control system.

1.7. Access or egress control system or delayed egress locking or latching system.

1.8. Fire damper.

1.9. Door control system.

2. One story detached structures used as tool and storage sheds, playhouses or similar uses, provided the building area does not exceed 256 square feet (23.78 m2) and the structures are not classified as a Group F-1 or H occupancy.

3. Detached prefabricated buildings housing the equipment of a publicly regulated utility service, provided the floor area does not exceed 150 square feet (14 m2).

4. Tents or air-supported structures, or both, that cover an area of 900 square feet (84 m2) or less, including within that area all connecting areas or spaces with a common means of egress or entrance, provided such tents or structures have an occupant load of 50 or less persons.

5. Fences of any height unless required for pedestrian safety as provided for by Section 3306, or used for the barrier for a swimming pool.

6. Concrete or masonry walls, provided such walls do not exceed six feet in height above the finished grade. Ornamental column caps shall not be considered to contribute to the height of the wall and shall be permitted to extend above the six feet height measurement.

7. Retaining walls supporting less than three feet of unbalanced fill that are not constructed for the purpose of impounding Class I, II or III-A liquids or supporting a surcharge other than ordinary unbalanced fill.

8. Swimming pools that have a surface area not greater than 150 square feet (13.95 m2), do not exceed 5,000 gallons (19 000 L) and are less than 24 inches (610 mm) deep.

9. Signs under the conditions in Section H101.2 of Appendix H.

10. Replacement of above-ground existing LP-gas containers of the same capacity in the same location and associated regulators when installed by the serving gas supplier.

11. Flagpoles 30 feet (9144 mm) or less in height.

12. Temporary ramps serving dwelling units in Group R-3 and R-5 occupancies where the height of the entrance served by the ramp is no more than 30 inches (762 mm) above grade.

13. Construction work deemed by the building official to be minor and ordinary and which does not adversely affect public health or general safety.

14. Ordinary repairs that include the following:

14.1. Replacement of windows and doors with windows and doors of similar operation and opening dimensions that do not require changes to the existing framed opening and that are not required to be fire rated in Group R-2 where serving a single dwelling unit and in Groups R-3, R-4 and R-5.

14.2. Replacement of plumbing fixtures and well pumps in all groups without alteration of the water supply and distribution systems, sanitary drainage systems or vent systems.

14.3. Replacement of general use snap switches, dimmer and control switches, 125 volt-15 or 20 ampere receptacles, luminaires (lighting fixtures) and ceiling (paddle) fans in Group R-2 where serving a single dwelling unit and in Groups R-3, R-4 and R-5.

14.4. Replacement of mechanical appliances provided such equipment is not fueled by gas or oil in Group R-2 where serving a single-family dwelling and in Groups R-3, R-4 and R-5.

14.5. Replacement of an unlimited amount of roof covering or siding in Groups R-3, R-4 or R-5 provided the building or structure is not in an area where the nominal design (3 second gust) wind speed is greater than 100 miles per hour (160 km/hr) (44.7 meters per second) and replacement of 100 square feet (9.29 m2) or less of roof covering in all groups and all wind zones.

14.6. Replacement of [ 100 256 ] square feet [ (9.29 m2) 23.78 m2 ] or less of roof decking in Groups R-3, R-4 or R-5 unless the decking to be replaced was required at the time of original construction to be fire-retardant-treated or protected in some other way to form a fire-rated wall termination.

14.7. Installation or replacement of floor finishes in all occupancies.

14.8. Replacement of Class C interior wall or ceiling finishes installed in Groups A, E and I and replacement of all classes of interior wall or ceiling finishes in other groups.

14.9. Installation or replacement of cabinetry or trim.

14.10. Application of paint or wallpaper.

14.11. Other repair work deemed by the building official to be minor and ordinary which does not adversely affect public health or general safety.

15. Crypts, mausoleums, and columbaria structures not exceeding 1500 square feet (139.35 m2) in area if the building or structure is not for occupancy and used solely for the interment of human or animal remains and is not subject to special inspections.

16. Billboard safety upgrades to add or replace steel catwalks, steel ladders, or steel safety cable.

[ Exception Exceptions ]:

[ 1. ] Application for a permit may be required by the building official for the installation of replacement siding, roofing and windows in buildings within a historic district designated by a locality pursuant to § 15.2-2306 of the Code of Virginia.

[ 2. Application for a permit may be required by the building official for any items exempted in this section that are located in a special flood hazard area. ]

C. Section 108.3 Applicant information, processing by mail. Application for a permit shall be made by the owner or lessee of the relevant property or the agent of either or by the RDP, contractor or subcontractor associated with the work or any of their agents. The full name and address of the owner, lessee and applicant shall be provided in the application. If the owner or lessee is a corporate body, when and to the extent determined necessary by the building official, the full name and address of the responsible officers shall also be provided.

A permit application may be submitted by mail and such permit applications shall be processed by mail, unless the permit applicant voluntarily chooses otherwise. In no case shall an applicant be required to appear in person.

The building official may accept applications for a permit through electronic submissions provided the information required by this section is obtained.

D. Section 108.4 Prerequisites to obtaining permit. In accordance with § 54.1-1111 of the Code of Virginia, any person applying to the building department for the construction, removal or improvement of any structure shall furnish prior to the issuance of the permit either (i) satisfactory proof to the building official that he is duly licensed or certified under the terms or Chapter 11 (§ 54.1-1000 et seq.) of Title 54.1 of the Code of Virginia to carry out or superintend the same or (ii) file a written statement, supported by an affidavit, that he is not subject to licensure or certification as a contractor or subcontractor pursuant to Chapter 11 of Title 54.1 of the Code of Virginia. The applicant shall also furnish satisfactory proof that the taxes or license fees required by any county, city, or town have been paid so as to be qualified to bid upon or contract for the work for which the permit has been applied.

E. Section 108.5 Mechanics' lien agent designation. In accordance with § 36-98.01 of the Code of Virginia, a building permit issued for any one-family or two-family residential dwelling shall at the time of issuance contain, at the request of the applicant, the name, mailing address, and telephone number of the mechanics' lien agent as defined in § 43-1 of the Code of Virginia. If the designation of a mechanics' lien agent is not so requested by the applicant, the building permit shall at the time of issuance state that none has been designated with the words "None Designated."

Note: In accordance with § 43-4.01A of the Code of Virginia, a permit may be amended after it has been initially issued to name a mechanics' lien agent or a new mechanics' lien agent.

F. Section 108.6 Application form, description of work. The application for a permit shall be submitted on a form or forms supplied by the local building department. The application shall contain a general description and location of the proposed work and such other information as determined necessary by the building official.

G. Section 108.7 Amendments to application. An application for a permit may be amended at any time prior to the completion of the work governed by the permit. Additional construction documents or other records may also be submitted in a like manner. All such submittals shall have the same effect as if filed with the original application for a permit and shall be retained in a like manner as the original filings.

H. Section 108.8 Time limitation of application. An application for a permit for any proposed work shall be deemed to have been abandoned six months after the date of filing unless such application has been pursued in good faith or a permit has been issued, except that the building official is authorized to grant one or more extensions of time if a justifiable cause is demonstrated.

[ 13VAC5-63-130. Section 113 Inspections.