TITLE 13. HOUSING

REGISTRAR'S NOTICE: The Board of Housing and Community Development is claiming an exemption from Article 2 of the Administrative Process Act pursuant to § 2.2-4006 A 12 of the Code of Virginia, which excludes regulations adopted by the board pursuant to the Statewide Fire Prevention Code (§ 27-94 et seq.), the Industrialized Building Safety Law (§ 36-70 et seq.), the Uniform Statewide Building Code (§ 36-97 et seq.), and § 36-98.3 of the Code of Virginia, provided the board (i) provides a Notice of Intended Regulatory Action in conformance with the provisions of § 2.2-4007.01, (ii) publishes the proposed regulation and provides an opportunity for oral and written comments as provided in § 2.2-4007.03, and (iii) conducts at least one public hearing as provided in §§ 2.2-4009 and 36-100 prior to the publishing of the proposed regulations. The Board of Housing and Community Development will receive, consider, and respond to petitions regarding 13VAC5-63-210 by any interested person at any time with respect to reconsideration or revision.

Title of Regulation: 13VAC5-63. Virginia Uniform Statewide Building Code (amending 13VAC5-63-210).

Statutory Authority: § 36-98 of the Code of Virginia.

Public Hearing Information:

September 28, 2020 - 10 a.m. - Google Meet Meeting - The link to access the electronic meeting is meet.google.com/rqj-cmsq-rft, or copy and paste the link into a browser. Additional details and information are available on the Virginia Regulatory Town Hall (www.townhall.virginia.gov).

Public Comment Deadline: November 13, 2020.

Agency Contact: Kyle Flanders, Senior Policy Analyst, Department of Housing and Community Development, Main Street Centre, 600 East Main Street, Suite 300, Richmond, VA 23219, telephone (804) 786‑6761, FAX (804) 371‑7090, TTY (804) 371‑7089, or email kyle.flanders@dhcd.virginia.gov.

Background: The Uniform Statewide Building Code (USBC) is a regulation governing the construction, maintenance, and rehabilitation of new and existing building and structures. The USBC uses nationally recognized model building codes and standards produced by the International Code Council (ICC) and other standard-writing groups as the basis for the technical provisions of the regulation. Every three years, new editions of the model codes become available. At that time, the Board of Housing and Community Development (BHCD) initiates a regulatory action to incorporate the newest editions of the model codes into the regulation as well as accepting proposals for changes to the regulation from affected client groups and the public.

This proposed phase of the regulatory action only includes 13VAC5-63-210. The text of this section was published correctly in the Virginia Register of Regulations in Volume 36, Issue 12 on February 3, 2020. However, due to a technical error, certain information may not have been present on the Virginia Regulatory Town Hall website -- specifically, 13VAC5-63-210.

Summary:

The proposed substantive amendments to 13VAC5-63-210 do the following:

1. Make several changes to the Residential Code, including updating REScheck to the 2018 International Energy Conservation Code (IECC).

2. Eliminate the deletion of the energy certificate requirement and revise the section to allow the certificate to be kept at an offsite location for multifamily buildings.

3. Remove visual option and require blower door testing for air leakage rate of buildings (5 air changes).

4. Remove prohibition against using building cavities as plenums.

5. Remove the requirement for residential exhaust hoods in kitchens for grease laden vapors as the requirements for this are specified in the International Mechanical Code and do not belong in the IECC.

6. Revise landing/floor height requirement for exterior doors from to 8-1/4 inches.

7. Allow the use of Appendix Q for tiny houses (i.e., dwellings 400 square feet or less).

8. Revise foundation anchorage language to match the International Building Code.

9. Clarify that only one foundation vent is required within three feet of each corner.

10. Add an option for relining existing building sewers and building draining piping.

11. Add an option to provide a notice by electronic means for a local board of building code appeals hearing.

12. Change the minimum slope from two percent to one percent for drainage on impervious surfaces within 10 feet of the building foundation.

Other proposed changes update citations to incorporated codes and statutes, reorganize standards for a more appropriate placement in the code, or clarify or correlate provisions.

13VAC5-63-210. Chapter 3 Use and occupancy classification.

A. Change Sections 303.1.1 and 303.1.2 of the IBC to read:

303.1.1 Small buildings and tenant spaces. A building or tenant space used for assembly purposes with an occupant load of less than 50 persons shall be permitted to be classified as a Group B occupancy.

303.1.2 Small assembly spaces. The following rooms and spaces shall be permitted to be classified as Group B occupancies or as part of the assembly occupancy:

1. A room or space used for assembly purposes with an occupant load of less than 50 persons and ancillary to another occupancy.

2. A room or space used for assembly purposes that is less than 750 square feet (70 m2) in area and ancillary to another occupancy.

B. Change Section 303.6 of the IBC to read:

303.6 Assembly Group A-5. Assembly uses intended for participation in or viewing outdoor activities including, but not limited to:

Amusement park structures

Bleachers

Grandstands

Stadiums

Swimming pools

C. Add Section 304.1.1 to the IBC to read:

304.1.1 Day support and day treatment facilities. Day support and day treatment facilities licensed by the Virginia Department of Behavioral Health and Developmental Services shall be permitted to be classified as Group B occupancies provided all of the following conditions are met:

1. Participants who may require physical assistance from staff to respond to an emergency situation shall be located on the level of exit discharge.

2. Any change in elevation within the exit access on the level of exit discharge shall be made by means of a ramp or sloped walkway.

3. Where the facilities are located more than two stories above grade, an automatic sprinkler system shall be provided throughout the building in accordance with Section 903.3.1.1.

D. Change exception Exception 14 of Section 307.1.1 of the IBC and add exception 15 Exception 18 to Section 307.1.1 of the IBC to read:

14. The storage of black powder, smokeless propellant and small arms primers in Groups M, R-3 and R-5 and special industrial explosive devices in Groups B, F, M and S, provided such storage conforms to the quantity limits and requirements prescribed in the IFC, as amended in Section 307.9.

15. 18. The storage of distilled spirits and wines in wooden barrels and casks. Distillation, blending, bottling, and other hazardous materials storage or processing shall be in separate control areas complying with Section 414.2.

E. Change the "Flammable liquid, combination (IA, IB, IC)" row in Table 307.1(1), add a new "Permissible fireworks" row to Table 307.1(1) of the IBC, and add footnote "r" to Table 307.1(1) of the IBC to read:

Flammable liquid, combination (IA, IB, IC) | NA | H-2 or H-3 | NA | 120d,e,h | NA | NA | 120d,h | NA | NA | 30d,h,r |

Permissible fireworks | 1.4G | H-3 | 125d,e,l | NA | NA | NA | NA | NA | NA | NA |

r. The tabular value for distilled spirit distillation and blending rooms is 120 gallons. |

F. Add Section 307.9 to the IBC to read:

307.9 Amendments. The following changes shall be made to the IFC for the use of Exception 14 in Section 307.1.1:

1. Change the following definition in Section 202 of the IFC to read:

Smokeless propellants. Solid propellants, commonly referred to as smokeless powders, or any propellants classified by DOTn as smokeless propellants in accordance with NA3178 (Smokeless Powder for Small Arms), used in small arms ammunition, firearms, cannons, rockets, propellant-actuated devices, and similar articles.

2. Change Section 314.1 of the IFC to read as follows:

314.1 General. Indoor displays constructed within any building or structure shall comply with Sections 314.2 through 314.5.

3. Add new Section 314.5 to the IFC to read as follows:

314.5 Smokeless powder and small arms primers. Vendors shall not store, display or sell smokeless powder or small arms primers during trade shows inside exhibition halls except as follows:

1. The amount of smokeless powder each vender may store is limited to the storage arrangements and storage amounts established in Section 5606.5.2.1.

2. Smokeless powder shall remain in the manufacturer's original sealed container and the container shall remain sealed while inside the building. The repackaging of smokeless powder shall not be performed inside the building. Damaged containers shall not be repackaged inside the building and shall be immediately removed from the building in such manner to avoid spilling any powder.

3. There shall be at least 50 feet separation between vendors and 20 feet from any exit.

4. Small arms primers shall be displayed and stored in the manufacturer's original packaging and in accordance with the requirements of Section 5606.5.2.3.

4. Change Exception 4 and add Exceptions 10 and 11 to Section 5601.1 of the IFC as follows:

4. The possession, storage and use of not more than 15 pounds (6.75 kg) of commercially manufactured sporting black powder, 20 pounds (9 kg) of smokeless powder and any amount of small arms primers for hand loading of small arms ammunition for personal consumption.

10. The display of small arms primers in Group M when in the original manufacturer's packaging.

11. The possession, storage and use of not more than 50 pounds (23 kg) of commercially manufactured sporting black powder, 100 pounds (45 kg) of smokeless powder, and small arms primers for hand loading of small arms ammunition for personal consumption in Group R-3 or R-5, or 200 pounds (91 kg) of smokeless powder when stored in the manufacturer's original containers in detached Group U structures at least 10 feet (3048 mm) from inhabited buildings and are accessory to Group R-3 or R-5.

5. Change Section 5606.4 of the IFC to read as follows:

5606.4 Storage in residences. Propellants for personal use in quantities not exceeding 50 pounds (23 kg) of black powder or 100 pounds (45 kg) of smokeless powder shall be stored in original containers in occupancies limited to Group Groups R-3 and R-5 or 200 pounds (91 kg) of smokeless powder when stored in the manufacturer's original containers in detached Group U structures at least 10 feet (3048 mm) from inhabited buildings and are accessory to Group R-3 or R-5. In other than Group R-3 or R-5, smokeless powder in quantities exceeding 20 pounds (9 kg) but not exceeding 50 pounds (23 kg) shall be kept in a wooden box or cabinet having walls of at least one inch (25 mm) nominal thickness or equivalent.

6. Delete Sections 5606.4.1 and 5606.4.2 of the IFC.

7. Change Section 5606.5.1.1 of the IFC to read as follows:

5606.5.1.1 Smokeless propellant. No more than 100 pounds (45 kg) of smokeless propellants in containers of eight pounds (3.6 kg) or less capacity shall be displayed in Group M occupancies.

8. Delete Section 5606.5.1.3 of the IFC.

9. Change Section 5606.5.2.1 of the IFC as follows:

5606.5.2.1 Smokeless propellant. Commercial stocks of smokeless propellants shall be stored as follows:

1. Quantities exceeding 20 pounds (9 kg), but not exceeding 100 pounds (45 kg) shall be stored in portable wooden boxes having walls of at least one inch (25 mm) nominal thickness or equivalent.

2. Quantities exceeding 100 pounds (45 kg), but not exceeding 800 pounds (363 kg), shall be stored in storage cabinets having walls at least one inch (25 mm) nominal thickness or equivalent. Not more than 400 pounds (182 kg) shall be stored in any one cabinet, and cabinets shall be separated by a distance of at least 25 feet (7620 mm) or by a fire partition having a fire-resistance rating of at least one hour.

3. Storage of quantities exceeding 800 pounds (363 kg), but not exceeding 5,000 pounds (2270 kg) in a building shall comply with all of the following:

3.1. The warehouse or storage room is inaccessible not open to unauthorized personnel.

3.2. Smokeless propellant shall be stored in nonportable storage cabinets having wood walls at least one inch (25 mm) nominal thickness or equivalent and having shelves with no more than 3 feet (914 mm) of vertical separation between shelves.

3.3. No more than 400 pounds (182 kg) is stored in any one cabinet.

3.4. Cabinets shall be located against walls with at least 40 feet (12 192 (12,192 mm) between cabinets. The minimum required separation between cabinets may be reduced to 20 feet (6096 mm) provided that barricades twice the height of the cabinets are attached to the wall, midway between each cabinet. The barricades must extend a minimum of 10 feet (3048 mm) outward, be firmly attached to the wall, and be constructed of steel not less than 0.25 inch thick (6.4 mm), 2-inch (51 mm) nominal thickness wood, brick, or concrete block.

3.5. Smokeless propellant shall be separated from materials classified as combustible liquids, flammable liquids, flammable solids, or oxidizing materials by a distance of 25 feet (7620 mm) or by a fire partition having a fire-resistance rating of 1 hour.

3.6. The building shall be equipped throughout with an automatic sprinkler system installed in accordance with Section 903.3.1.1.

4. Smokeless propellants not stored according to Item 1, 2, or 3 above shall be stored in a Type 2 or 4 magazine in accordance with Section 5604 and NFPA 495.

G. Add the following to the list of terms in Section 308.2 of the IBC:

Hospice facility

H. G. Change Section 308.3 308.2 of the IBC to read:

308.3 308.2 Institutional Group I-1. This occupancy shall include buildings, structures or portions thereof for more than 16 persons, excluding staff, who reside on a 24-hour basis in a supervised environment and receive custodial care. Buildings of Group I-1, other than assisted living facilities licensed by the Virginia Department of Social Services, shall be classified as the occupancy condition indicated in Section 308.3.1 308.2.1. Assisted living facilities licensed by the Virginia Department of Social Services shall be classified as one of the occupancy conditions indicated in Section 308.3.1 308.2.1 or 308.3.2 308.2.2. This group shall include, but not be limited to, the following:

Alcohol and drug centers

Assisted living facilities

Congregate care facilities

Group homes

Halfway houses

Residential board and care facilities

Social rehabilitation facilities

I. H. Change Sections 308.3.1 308.2.1 and 308.3.2 308.2.2 of the IBC to read:

308.3.1 308.2.1 Condition 1. This occupancy condition shall include buildings in which all persons receiving custodial care who, without any assistance, are capable of responding to an emergency situation to complete building evacuation. Not more than five of the residents may require physical assistance from staff to respond to an emergency situation when all residents who may require the physical assistance reside on a single level of exit discharge.

308.3.2 308.2.2 Condition 2. This occupancy condition shall include buildings in which there are persons receiving custodial care who require assistance by not more than one staff member while responding to an emergency situation to complete building evacuation. Five of the residents may require physical assistance from more than one staff member to respond to an emergency.

J. I. Change Section 308.4 308.3 of the IBC to read:

308.4 308.3 Group I-2. This occupancy shall include buildings and structures used for medical care on a 24-hour basis for more than five persons who are incapable of self-preservation. This group shall include, but not be limited to, the following:

Convalescent facilities

Detoxification facilities

Foster care facilities

Hospice facilities

Hospitals

Nursing homes

Psychiatric hospitals

Exception: Hospice facilities occupied by 16 or less occupants, excluding staff, are permitted to be classified as Group R-4.

K. J. Add an exception to Section 308.6 308.5 of the IBC to read:

Exception: Family day homes under Section 310.9 310.8.

L. K. Change Section 310.3 310.2 of the IBC to read:

310.3 310.2 Residential Group R-1. Residential occupancies containing sleeping units where the occupants are primarily transient in nature, including:

Boarding houses (transient) with more than 10 occupants

Congregate living facilities (transient) with more than 10 occupants

Hotels (transient)

Motels (transient)

Exceptions:

1. Nonproprietor occupied bed and breakfast and other transient boarding facilities not more than three stories above grade plane in height with a maximum of 10 occupants total are permitted to be classified as either Group R-3 or R-5 provided that smoke alarms are installed in compliance with Section 907.2.11.2 907.2.10.2 for Group R-3 or Section R314 of the IRC for Group R-5.

2. Proprietor occupied bed and breakfast and other transient boarding facilities not more than three stories above grade plane in height, that are also occupied as the residence of the proprietor, with a maximum of five guest room sleeping units provided for the transient occupants are permitted to be classified as either Group R-3 or R-5 provided that smoke alarms are installed in compliance with Section 907.2.11.2 907.2.10.2 for Group R-3 or Section R314 of the IRC for Group R-5.

M. L. Change Section 310.6 310.5 of the IBC to read:

310.6 310.5 Residential Group R-4. This occupancy shall include buildings, structures or portions thereof for more than five but not more than 16 persons, excluding staff, who reside on a 24-hour basis in a supervised environment and receive custodial care. Buildings of Group R-4, other than assisted living facilities licensed by the Virginia Department of Social Services, shall be classified as the occupancy condition indicated in Section 310.6.1 310.5.1. Assisted living facilities licensed by the Virginia Department of Social Services shall be classified as one of the occupancy conditions indicated in Section 310.6.1 310.5.1 or 310.6.2 310.5.2. This group shall include, but not be limited to the following:

Alcohol and drug centers

Assisted living facilities

Congregate care facilities

Group homes

Halfway houses

Residential board and care facilities

Social rehabilitation facilities

This occupancy shall also include hospice facilities with not more than 16 occupants, excluding staff.

Group R-4 occupancies shall meet the requirements for construction as defined for Group R-3, except as otherwise provided for in this code.

Exceptions:

1. Group homes licensed by the Virginia Department of Behavioral Health and Developmental Services that house no more than eight persons with one or more resident counselors shall be classified as Group R-2, R-3, R-4 or R-5. Not more than five of the persons may require physical assistance from staff to respond to an emergency situation.

2. In Group R-4 occupancies classified as the occupancy condition indicated in Section 310.6.1 310.5.1, other than in hospice facilities, not more than five of the residents may require physical assistance from staff to respond to an emergency situation when all residents who may require the physical assistance from staff reside on a single level of exit discharge and other than using a ramp, a change of elevation using steps or stairs is not within the path of egress to an exit door.

3. Assisted living facilities licensed by the Virginia Department of Social Services that house no more than eight persons, with one or more resident counselors, and all of the residents are capable of responding to an emergency situation without physical assistance from staff, may be classified as Group R-2, R-3 or R-5.

4. Assisted living facilities licensed by the Virginia Department of Social Services that house no more than eight persons, with one or more resident counselors, may be classified as Group R-5 when in compliance with all of the following:

4.1. The building is protected by an automatic sprinkler system installed in accordance with Section 903.3 or Section P2904 of the IRC.

4.2. Not more than five of the residents may require physical assistance from staff to respond to an emergency situation.

4.3. All residents who may require physical assistance from staff to respond to an emergency situation reside on a single level of exit discharge and other than using a ramp, a change in elevation using steps or stairs is not within the path of egress to an exit door.

5. Hospice facilities with five or fewer occupants are permitted to comply with the IRC provided the building is protected by an automatic sprinkler system in accordance with IRC Section P2904 or IBC Section 903.3.

N. M. Change Sections 310.6.1 310.5.1 and 310.6.2 310.5.2 to the IBC to read:

310.6.1 310.5.1 Condition 1. This occupancy condition shall include buildings in which all persons receiving custodial care who, without any assistance, are capable of responding to an emergency situation to complete building evacuation and hospice facilities.

310.6.2 310.5.2 Condition 2. This occupancy condition shall include buildings in which there are persons receiving custodial care who require assistance by not more than one staff member while responding to an emergency situation to complete building evacuation.

O. N. Add Section 310.7 310.6 to the IBC to read:

310.7 310.6 Residential Group R-5. Residential occupancies in detached single-family and two-family dwellings, townhouses and accessory structures within the scope of the IRC.

P. O. Add Section 310.8 310.7 to the IBC to read:

310.8 Group R-5. The construction of Group R-5 structures shall comply with the IRC. The amendments to the IRC set out in Section 310.11 310.10 shall be made to the IRC for its use as part of this code. In addition, all references to the IRC in the IBC shall be considered to be references to this section.

Q. P. Add Section 310.8.1 310.7.1 to the IBC to read:

310.8.1 310.7.1 Additional requirements. Methods of construction, materials, systems, equipment or components for Group R-5 structures not addressed by prescriptive or performance provisions of the IRC shall comply with applicable IBC requirements.

R. Q. Add Section 310.9 310.8 to the IBC to read:

310.9 310.8 Family day homes. Family day homes where program oversight is provided by the Virginia Department of Social Services shall be classified as Group R-2, R-3 or R-5.

Note: Family day homes may generally care for up to 12 children. See the DHCD Related Laws Package for additional information.

S. R. Add Section 310.10 310.9 to the IBC to read:

310.10 310.9 Radon-resistant construction in Groups R-3 and R-4 structures. Groups R-3 and R-4 structures shall be subject to the radon-resistant construction requirements in Appendix F of the IRC in localities enforcing such requirements pursuant to Section R324 of the IRC.

T. S. Add Section 310.11 310.10 to the IBC to read:

310.11 310.10 Amendments to the IRC. The following changes shall be made to the IRC for its use as part of this code:

1. Add the following definitions to read:

Living area. Space within a dwelling unit utilized for living and entertainment, including family rooms, great rooms, living rooms, dens, media rooms, and similar spaces.

Nonpotable fixtures and outlets. Fixtures and outlets that are not dependent on potable water for the safe operation to perform their intended use. Such fixtures and outlets may include, but are not limited to water closets, urinals, irrigation, mechanical equipment, and hose connections to perform operations, such as vehicle washing and lawn maintenance.

Nonpotable water systems. Water systems for the collection, treatment, storage, distribution, and use or reuse of nonpotable water. Nonpotable systems include reclaimed water, rainwater, and gray water systems.

Rainwater. Natural precipitation, including snow melt, from roof surfaces only.

Stormwater. Precipitation that is discharged across the land surface or through conveyances to one or more waterways and that may include stormwater runoff, snow melt runoff, and surface runoff and drainage.

2. Change the following definitions to read:

Attic, habitable. A finished or unfinished area, not considered a story, complying with all of the following requirements:

1. The occupiable floor area is at least 70 square feet (17 m2), in accordance with Section R304,

2. The occupiable floor area has a ceiling height in accordance with Section R305, and

3. The occupiable space is enclosed by the roof assembly above, knee walls (if applicable) on the sides and the floor-ceiling assembly below.

Habitable attics greater than two-thirds of the area of the story below or over 400 square feet (37.16 m2) shall not be permitted in dwellings or townhouses that are three stories above grade plane in height.

Gray water. Water discharged from lavatories, bathtubs, showers, clothes washers, and laundry trays.

3. Change Section R301.2.1 to read:

R301.2.1 Wind design criteria. Buildings and portions thereof shall be constructed in accordance with the wind provisions of this code using the ultimate design wind speed in Table R301.2(1) as determined from Figure R301.2(4)A R301.2(5)A. The structural provisions of this code for wind loads are not permitted where wind design is required as specified in Section R301.2.1.1. Where different construction methods and structural materials are used for various portions of a building, the applicable requirements of this section for each portion shall apply. Where not otherwise specified, the wind loads listed in Table R301.2(2) adjusted for height and exposure using Table R301.2(3) shall be used to determine design load performance requirements for wall coverings, curtain walls, roof coverings, exterior windows, skylights, garage doors, and exterior doors. Asphalt shingles shall be designed for wind speeds in accordance with Section R905.2.4. A continuous load path shall be provided to transmit the applicable uplift forces in Section R802.11.1 from the roof assembly to the foundation. Wind speeds for localities in special wind regions, near mountainous terrain, and near gorges shall be based on elevation. Areas at 4,000 feet in elevation or higher shall use the nominal design wind speed of 110 mph (48.4 m/s) and areas under 4,000 feet in elevation shall use nominal design wind speed of 90 mph (39.6 m/s). Gorge areas shall be based on the highest recorded speed per locality or in accordance with local jurisdiction requirements determined in accordance with Section 26.5.1 of ASCE 7.

4. Add Exceptions 6 and 7 to Section R302.1 to read:

6. Decks and open porches.

7. Walls of dwellings and accessory structures located on lots in subdivisions or zoning districts where building setbacks established by local ordinance prohibit the walls of the structures on adjacent lots from being closer than 10 feet (3048 mm) to each other at any point along the exterior walls.

5. Add the following sentence to the end of Section R302.3 to read:

Dwelling unit separation wall assemblies that are constructed on a lot line shall be constructed as required in Section R302.2 for townhouses.

6. Change Section R302.5.1 to read and delete Section R302.13 in its entirety:

R302.5.1 Opening protection. Openings from a private garage directly into a room used for sleeping purposes shall not be permitted. Other openings between the garage and residence shall be equipped with solid wood doors not less than 1‑3/8 inches (35 mm) thickness, solid or honeycomb-core steel doors not less than 1‑3/8 inches (35 mm) thick, or 20-minute fire-rated doors.

7. Delete Section R302.13 in its entirety.

8. Change Section R303.4 to read:

R303.4 Mechanical ventilation. Dwelling units shall be provided with mechanical ventilation in accordance with Section M1507 M1505.

8. 9. Add an exception to Section R303.10 to read:

Exception: Seasonal structures not used as a primary residence for more than 90 days per year, unless rented, leased or let on terms expressed or implied to furnish heat, shall not be required to comply with this section.

9. 10. Add Section R303.10.1 to read:

R303.10.1 Nonowner occupied required heating. Every dwelling unit or portion thereof which is to be rented, leased or let on terms either expressed or implied to furnish heat to the occupants thereof shall be provided with facilities in accordance with Section R303.9 R303.10 during the period from October 15 to May 1.

10. 11. Add Section R303.11 to read:

R303.11 Insect screens. Every door, window and other outside opening required for ventilation purposes shall be supplied with approved tightly fitted screens of not less than 16 mesh per inch (16 mesh per 25 mm) and every screen door used for insect control shall have a self-closing device.

11. 12. Add Section R306.5 to read:

R306.5 Water supply sources and sewage disposal systems. The water and drainage system of any building or premises where plumbing fixtures are installed shall be connected to a public or private water supply and a public or private sewer system. As provided for in Section 103.5 of Part I of the Virginia Uniform Statewide Building Code (13VAC5-63), for functional design, water supply sources and sewage disposal systems are regulated and approved by the Virginia Department of Health and the Virginia Department of Environmental Quality.

Note: See also the Memorandums of Agreement in the "Related Laws Package," which is available from the Virginia Department of Housing and Community Development.

12. 13. Change Section R308.4.5 to read:

R308.4.5 Glazing and wet surfaces. Glazing in walls, enclosures, or fences containing or facing hot tubs, spas, whirlpools, saunas, steam rooms, bathtubs, showers, and indoor or outdoor swimming pools shall be considered a hazardous location if located less than 60 inches (1524 mm) measured horizontally, in a straight line, from the water's edge and the bottom exposed edge of the glazing is less than 60 inches (1524 mm) measured vertically above any standing or walking surface. This shall apply to single glazing and each pane in multiple glazing.

13. 14. Change Section R310.1 to read:

R310.1 Emergency escape and rescue opening required. Basements, habitable attics, and every sleeping room designated on the construction documents shall have not less than one operable emergency escape and rescue opening. Where basements contain one or more sleeping rooms, an emergency egress and rescue opening shall be required in each sleeping room. Emergency escape and rescue openings shall open directly into a public way, or to a yard or court that opens to a public way.

Exceptions:

1. Dwelling units equipped throughout with an approved automatic sprinkler system installed in accordance with NFPA 13, 13R, or 13D or Section P2904.

2. Storm shelters and basements used only to house mechanical equipment and not exceeding total floor area of 200 square feet (18.58 m2).

14. 15. Change Section R310.2.1 to read:

R310.2.1 Minimum opening area. Emergency and escape rescue openings shall have a net clear opening of not less than 5.7 square feet (0.530 m2). The net clear opening dimensions required by this section shall be obtained by the normal operation of the emergency escape and rescue opening from the inside, including the tilting or removal of the sash as the normal operation. The net clear height opening shall be not less than 24 inches (610 mm), and the net clear width shall be not less than 20 inches (508 mm).

Exception: Grade floor or below grade openings shall have a net clear opening of not less than 5 square feet (0.465 m2).

15. 16. Change the exception in to Section R311.3.1 to read:

Exception: The landing or floor on the exterior side shall not be more than 8-1/4 inches (210 mm) below the top of the threshold provided the door does not swing over the landing or floor.

16. 17. Change Section R311.3.2 to read:

R311.3.2 Floor elevations for other exterior doors. Doors other than the required egress door shall be provided with landings or floors not more than 8‑1/4 inches (210 mm) below the top of the threshold.

Exception: A top landing is not required where a stairway of not more than two risers is located on the exterior side of the door, if that door does not swing over the stairway.

18. Change Section R311.7.5.1 to read:

R311.7.5.1 Risers. The riser height shall be not more than 8-1/4 inches (210 mm). The riser shall be measured vertically between the leading edges of the adjacent treads. The greatest riser height within any flight of stairs shall not exceed the smallest by more than 3/8 inch (9.5 mm). Risers shall be vertical or sloped from the underside of the nosing of the tread above at an angle not more than 30 degrees (0.51 rad) from the vertical. Open risers are permitted provided that the openings located more than 30 inches (763 mm), as measured vertically, to the floor or grade below do not permit the passage of a 4-inch-diameter (102 mm) sphere.

Exceptions:

1. The opening between adjacent treads is not limited on spiral stairways.

2. The riser height of spiral stairways shall be in accordance with Section R311.7.10.1.

17. 19. Change Section R311.7.5.2 to read:

R311.7.5.2 Treads. The tread depth shall be not less than 9 inches (229 mm). The tread depth shall be measured horizontally between the vertical planes of the foremost projection of adjacent treads and at a right angle to the tread's leading edge. The greatest tread depth within any flight of stairs shall not exceed the smallest by more than 3/8 inch (9.5 mm).

18. 20. Change Section R311.7.7 to read:

R311.7.7 Stairway walking surface. The walking surface of treads and landings of stairways shall be level or sloped no steeper than one unit vertical in 48 units horizontal (2.0% slope).

19. 21. Change Section R312.2.1 to read:

R312.2.1 Window sills. In dwelling units, where the top of the sill of an operable window opening is located less than 18 inches (457 mm) above the finished floor and greater than 72 inches (1829 mm) above the finished grade or other surface below on the exterior of the building, the operable window shall comply with one of the following:

1. Operable windows with openings that will not allow a 4-inch-diameter (102 mm) sphere to pass through the opening where the opening is in its largest opened position.

2. Operable windows that are provided with window fall prevention devices that comply with ASTM F 2090.

3. Operable windows that are provided with window opening control devices that comply with Section R312.2.2.

20. 22. Replace Section R313 with the following:

Section R313.

Automatic Fire Sprinkler Systems.

R313.1 Townhouse automatic fire sprinkler systems. Notwithstanding the requirements of Section 103.3, where installed, an automatic residential fire sprinkler system for townhouses shall be designed and installed in accordance with NFPA 13D or Section P2904.

Exception: An automatic residential fire sprinkler system shall not be required when additions or alterations are made to existing townhouses that do not have an automatic residential fire sprinkler system installed.

R313.2 One-family and two-family dwellings automatic fire sprinkler systems. Notwithstanding the requirements of Section 103.3, where installed, an automatic residential fire sprinkler system shall be designed and installed in accordance with NFPA 13D or Section P2904.

Exception: An automatic residential fire sprinkler system shall not be required for additions or alterations to existing buildings that are not already provided with an automatic residential fire sprinkler system.

21. 23. Delete Section R314.2.2.

22. 24. Change Section R314.7.3 to read:

R314.7.3 Permanent fixture. Where a household fire alarm system is installed, it shall become a permanent fixture of the dwelling unit.

23. 25. Change Section R315.1.1 to read:

R315.1.1 Listings. Carbon monoxide alarms shall be hard wired, plug-in or battery type; listed as complying with UL 2034; and installed in accordance with this code and the manufacturer's installation instructions. Combination carbon monoxide and smoke alarms shall be listed in accordance with UL 2034 and UL 217.

24. 26. Change Section R315.2 to read:

R315.2 Where required. Carbon monoxide alarms shall be provided in accordance with this section.

25. 27. Delete Section R315.2.2.

26. 28. Delete Section R315.5 R315.6.

27. 29. Change Section R315.6.3 R315.7.3 to read:

R315.6.3 R315.7.3 Permanent fixture. Where a household carbon monoxide detection system is installed, it shall become a permanent fixture of the occupancy.

28. 30. Add Section R320.2 to read:

R320.2 Universal design features for accessibility in dwellings. Dwellings constructed under the IRC not subject to Section R320.1 may comply with Section 1109.16 of the USBC and be approved by the local building department as dwellings containing universal design features for accessibility.

29. 31. Add Section R326.1.1 to read:

R326.1.1 Changes to the ISPSC. The following change shall be made to the ISPSC:

1. Change Section 305.2.9 to read:

305.2.9 Equipment clear zone. Equipment, including pool equipment such as pumps, filters, and heaters shall not be installed within 36 inches (914 mm) of the exterior of the barrier when located on the same property.

30. 32. Add Section R327 R328 Radon-Resistant Construction.

31. 33. Add Section R327.1 R328.1 to read:

R327.1 R328.1 Local enforcement of radon requirements. Following official action under Article 7 (§ 15.2-2280 et seq.) of Chapter 22 of Title 15.2 of the Code of Virginia by a locality in areas of high radon potential, as indicated by Zone 1 on the U.S. EPA Map of Radon Zones (IRC Figure AF101), such locality shall enforce the provisions contained in Appendix F.

Exception: Buildings or portions thereof with crawl space foundations which are ventilated to the exterior, shall not be required to provide radon-resistant construction.

32. 34. Add Section R328 R329 Patio Covers.

33. 35. Add Section R328.1 R329.1 to read:

R328.1 R329.1 Use of Appendix H for patio covers. Patio covers shall comply with the provisions in Appendix H.

34. 36. Add Section R329 R330 Sound Transmission.

35. 37. Add Section R329.1 R330.1 to read:

R329.1 R330.1 Sound transmission between dwelling units. Construction assemblies separating dwelling units shall provide airborne sound insulation as required in Appendix K.

36. 38. Add Section R329.2 R330.2 to read:

R329.2 R330.2 Airport noise attenuation. This section applies to the construction of the exterior envelope of detached one-family and two-family dwellings and multiple single-family dwellings (townhouses) not more than three stories high with separate means of egress within airport noise zones when enforced by a locality pursuant to § 15.2-2295 of the Code of Virginia. The exterior envelope of such structures shall comply with Section 1207.4 1206.4 of the state amendments to the IBC.

37. 39. Add Section R330 R331 Fire Extinguishers.

38. 40. Add Section R330.1 R331.1 to read:

R330.1 R331.1 Kitchen areas. Other than where the dwelling is equipped with an approved sprinkler system in accordance with Section R313, a fire extinguisher having a rating of 2-A:10-B:C or an approved equivalent type of fire extinguisher shall be installed in the kitchen area.

39. 41. Add Section R331 R332 Interior Passage.

40. 42. Add Sections R331.1 R332.1 through R331.6 R332.6 to read:

R331.1 R332.1 General. This section applies to new dwelling units that have both a kitchen and a living area on the same floor level as the egress door required by Section R311.2. This section is not applicable to additions, reconstruction, alteration, or repair.

R331.2 R332.2 Kitchen. One interior passage route from the egress door to the kitchen shall comply with R331.6 R332.6.

R331.3 R332.3 Living area. One interior passage route from the egress door to at least one living area shall comply with R331.6 R332.6.

R331.4 R332.4 Bedroom. Where the dwelling unit has a bedroom on the same floor level as the egress door, one interior passage route from the egress door to at least one bedroom shall comply with R331.6 R332.6.

R331.5 R332.5 Bathroom. Where a dwelling unit has a bathroom on the same floor level as the egress door, and the bathroom contains a water closet, lavatory, and bathtub or shower, one interior passage route from the egress door to at least one bathroom shall comply with R331.6 R332.6. Bathroom fixture clearances shall comply with R307 and access to fixtures is not required to comply with R331.6 R332.6.

R331.6 R332.6 Opening widths. Opening widths along the interior passage route required by this section shall comply with the following:

1. Cased openings shall provide a minimum 34 inch (864 mm) clear width.

2. Doors shall be a nominal 34 inch (864 mm) minimum width. Double doors are permitted to be used to meet this requirement.

43. Add Section R333 Tiny Houses.

44. Add Section R333.1 to read:

R333.1 General. Appendix Q may be used as an alternative to the requirements of this code where a dwelling is 400 square feet (37 m2) or less in floor area.

41. 45. Change Section R401.3 to read:

R401.3 Drainage. Surface drainage shall be diverted to a storm sewer conveyance or other approved point of collection that does not create a hazard to the dwelling unit. Lots shall be graded to drain surface water away from foundation walls. The grade shall fall a minimum of six inches (152 mm) within the first 10 feet (3048 mm).

Exception: Where lot lines, walls, slopes or other physical barriers prohibit six inches (152 mm) of fall within 10 feet (3048 mm), drains or swales shall be constructed to ensure drainage away from the structure. Impervious surfaces within 10 feet (3048 mm) of the building foundation shall be sloped a minimum of 2.0% 1.0% away from the building.

42. 46. Add the following exceptions to Section R403.1 to read:

Exceptions:

1. One-story detached accessory structures used as tool and storage sheds, playhouses and similar uses, not exceeding 256 square feet (23.7824 m2) of building area, provided all of the following conditions are met:

1.1. The building eave height is 10 feet or less.

1.2. The maximum height from the finished floor level to grade does not exceed 18 inches.

1.3. The supporting structural elements in direct contact with the ground shall be placed level on firm soil and when such elements are wood they shall be approved pressure preservative treated suitable for ground contact use.

1.4. The structure is anchored to withstand wind loads as required by this code.

1.5. The structure shall be of light-frame construction whose vertical and horizontal structural elements are primarily formed by a system of repetitive wood or light gauge steel framing members, with walls and roof of light weight material, not slate, tile, brick or masonry.

2. Footings are not required for ramps serving dwelling units in Group Groups R-3 and R-5 occupancies where the height of the entrance is no more than 30 inches (762 mm) above grade.

47. Change Section R403.1.6 to read:

R403.1.6 Foundation anchorage. Wood sill plates and wood walls supported directly on continuous foundations shall be anchored to the foundation in accordance with this section.

Cold-formed steel framing shall be anchored directly to the foundation or fastened to wood sill plates in accordance with Section R505.3.1 or R603.3.1, as applicable. Wood sill plates supporting cold-formed steel framing shall be anchored to the foundation in accordance with this section.

Wood foundation plates or sills shall be bolted or anchored to the foundation with not less than 1/2-inch-diameter (12.7 mm) steel bolts or approved anchors spaced to provide equivalent anchorage as the steel bolts. Bolts shall be embedded not less than 7 inches (178 mm) into concrete or grouted cells of concrete masonry units. The bolts shall be located in the middle third of the width of the plate. Bolts shall be spaced not more than 6 feet (1829 mm) on center and there shall be not less than two bolts or anchor straps per piece with one bolt or anchor strap located not more than 12 inches (305 mm) or less than 4 inches (102 mm) from each end of each piece. A properly sized nut and washer shall be tightened on each bolt to the plate. Interior bearing wall sole plates on monolithic slab foundation that are not part of a braced wall panel shall be positively anchored with approved fasteners. Sill plates and sole plates shall be protected against decay and termites where required by Sections R317 and R318.

Exceptions:

1. Walls 24 inches (610 mm) total length or shorter connecting offset braced wall panels shall be anchored to the foundation with not fewer than one anchor bolt located in the center third of the plate section and shall be attached to adjacent braced wall panels at corners as shown in Item 9 of Table R602.3(1).

2. Connection of walls 12 inches (305 mm) total length or shorter connecting offset braced wall panels to the foundation without anchor bolts shall be permitted. The wall shall be attached to adjacent braced wall panels at corners as shown in Item 9 of Table R602.3(1).

43. 48. Delete Section R404.1.9.2.

49. Change Sections R408.1, R408.2, and R408.3 to read:

R408.1 Moisture control. The under-floor space between the bottom of the floor joists and the earth under any building (except space occupied by a basement) shall comply with Section R408.2 or R408.3.

R408.2 Openings for under-floor ventilation. Ventilation openings through foundation or exterior walls surrounding the under-floor space shall be provided in accordance with this section. The minimum net area of ventilation openings shall be not less than 1 square foot (0.0929 m2) for each 150 square feet (14 m2) of under-floor area. One ventilation opening shall be within 3 feet (915 mm) of each external corner of the under-floor space. Ventilation openings shall be covered for their height and width with any of the following materials provided that the least dimension of the covering shall not exceed 1/4 inch (6.4 mm), and operational louvers are permitted:

1. Perforated sheet metal plates not less than 0.070 inch (1.8 mm) thick.

2. Expanded sheet metal plates not less than 0.047 inch (1.2 mm) thick.

3. Cast-iron grill or grating.

4. Extruded load-bearing brick vents.

5. Hardware cloth of 0.035 inch (0.89 mm) wire or heavier.

6. Corrosion-resistant wire mesh, with the least dimension being 1/8 inch (3.2 mm) thick.

Exceptions:

1. The total area of ventilation openings shall be permitted to be reduced to 1/1,500 of the under-floor area where the ground surface is covered with an approved Class I vapor retarder material.

2. Where the ground surface is covered with an approved Class I vapor retarder material, ventilation openings are not required to be within 3 feet (915 mm) of each external corner of the under-floor space provided the openings are placed to provide cross ventilation of the space.

R408.3 Unvented crawl space. For unvented under-floor spaces the following items shall be provided:

1. Exposed earth shall be covered with a continuous Class I vapor retarder. Joints of the vapor retarder shall overlap by 6 inches (152 mm) and shall be sealed or taped. The edges of the vapor retarder shall extend not less than 6 inches (152 mm) up the stem wall and shall be attached and sealed to the stem wall or insulation.

2. One of the following shall be provided for the under-floor space:

2.1. Continuously operated mechanical exhaust ventilation at a rate equal to 1 cubic foot per minute (0.47 L/s) for each 50 square feet (4.7 m2) of crawl space floor area, including an air pathway to the common area (such as a duct or transfer grille), and perimeter walls insulated in accordance with Section N1102.2.11 of this code.

2.2. Conditioned air supply sized to deliver at a rate equal to 1 cubic foot per minute (0.47 L/s) for each 50 square feet (4.7 m2) of under-floor area, including a return air pathway to the common area (such as a duct or transfer grille), and perimeter walls insulated in accordance with Section N1102.2.11 of this code.

2.3. Plenum in existing structures complying with Section M1601.5, if under-floor space is used as a plenum.

2.4. Dehumidification sized to provide 70 pints (33 liters) of moisture removal per day for every 1,000 square feet (93 m2) of crawl space floor area.

44. 50. Change the exception to Section R408.2 to read:

Exception: The total area of ventilation openings shall be permitted to be reduced to 1/1,500 of the under-floor area where the ground surface is covered with an approved Class I vapor retarder material and the required openings are placed to provide cross ventilation of the space. The installation of operable louvers shall not be prohibited nor shall the required openings need to be within three feet (915 mm) of each corner provided there is cross ventilation of the space.

45. 51. Add Section R408.3.1 to read:

R408.3.1 Termite inspection. Where an unvented crawl space is installed and meets the criteria in Section R408, the vertical face of the sill plate shall be clear and unobstructed and an inspection gap shall be provided below the sill plate along the top of any interior foundation wall covering. The gap shall be a minimum of one inch (25.4 mm) and a maximum of two inches (50.8 mm) in width and shall extend throughout all parts of any foundation that is enclosed. Joints between the sill plate and the top of any interior wall covering may be sealed.

Exceptions:

1. In areas not subject to damage by termites as indicated by Table R301.2(1).

2. Where other approved means are provided to inspect for potential damage.

Where pier and curtain foundations are installed as depicted in Figure R404.1.5(1), the inside face of the rim joist and sill plate shall be clear and unobstructed except for construction joints which may be sealed.

Exception: Fiberglass or similar insulation may be installed if easily removable.

46. 52. Change Section R506.2.1 to read:

R506.2.1 Fill. Fill material shall be free of vegetation and foreign material and shall be natural nonorganic material that is not susceptible to swelling when exposed to moisture. The fill shall be compacted to assure uniform support of the slab, and except where approved, the fill depth shall not exceed 24 inches (610 mm) for clean sand or gravel and 8 inches (203 mm) for earth.

Exception: Material other than natural material may be used as fill material when accompanied by a certification from an RDP and approved by the building official.

47. 53. Change Section R506.2.2 to read:

R506.2.2 Base. A 4-inch-thick (102 mm) base course consisting of clean graded sand, gravel or crushed stone passing a 2-inch (51 mm) sieve shall be placed on the prepared subgrade when the slab is below grade.

Exception: A base course is not required when the concrete slab is installed on well drained or sand-gravel mixture soils classified as Group I according to the United Soil Classification System in accordance with Table R405.1. Material other than natural material may be used as base course material when accompanied by a certification from an RDP and approved by the building official.

48. Change Item 4 in Table R602.3(1) to read:

4

| Ceiling joist attached to parallel rafter (heel joint) (see Sections R802.3.1 and R802.3.2 and Table R802.5.1(9))

| Table R802.5.2

| Face nail

|

49. Change Table R602.7(1) to read:

EDITOR'S NOTE: Table R602.7(1), Girder Spansa and Header Spansa for Exterior Bearing Walls, is deleted in its entirety; therefore, the text of Table R602.7(1) is not set out.

50. Change Table R602.7(2) to read:

EDITOR'S NOTE: Table R602.7(2), Girder Spansa and Header Spansa for Interior Bearing Walls, is deleted in its entirety; therefore, the text of Table R602.7(2) is not set out.

51. 54. Change Section R602.10 to read:

R602.10 Wall bracing. Buildings shall be braced in accordance with this section or Section R602.12. Where a building, or portion thereof, does not comply with one or more of the bracing requirements in this section, those portions shall be designed and constructed in accordance with Section R301.1.

The building official shall be permitted to require the permit applicant to identify braced wall lines and braced wall panels on the construction documents as described in this section and provide associated analysis. The building official shall be permitted to waive the analysis of the upper floors where the cumulative length of wall openings of each upper floor wall is less than or equal to the length of the openings of the wall directly below.

52. 55. Change Section R602.10.9 to read:

R602.10.9 Braced wall panel support. Braced wall panel support shall be provided as follows:

1. Cantilevered floor joists complying with Section R502.3.3 shall be permitted to support braced wall panels.

2. Raised floor system post or pier foundations supporting braced wall panels shall be designed in accordance with accepted engineering practice.

3. Masonry stem walls with a length of 48 inches (1219 mm) or less supporting braced wall panels shall be reinforced in accordance with Figure R602.10.9. Masonry stem walls with a length greater than 48 inches (1219 mm) supporting braced wall panels shall be constructed in accordance with Section R403.1 Methods ABW and PFH shall not be permitted to attach to masonry stem walls.

4. Concrete stem walls with a length of 48 inches (1219 mm) or less, greater than 12 inches (305 mm) tall and less than 6 inches (152 mm) thick shall have reinforcement sized and located in accordance with Figure R602.10.9.

Exception: For masonry stem walls, an approved post-installed adhesive anchoring system shall be permitted as an alternative to the Optional Stem Wall Reinforcement detail in Figure R602.10.9. A minimum of two anchors shall be installed as indicated in Figure R602.10.9. Anchors shall be located not more than 4 inches (102 mm) from each end of the stem wall. Anchors shall be installed into the concrete footing as follows:

1. Five-eighth inch (16 mm) treaded rod using a 3/4 inch (19 mm) diameter drilled hole with a minimum embedment of 6 inches (152 mm).

2. Number 4 size reinforcing bar using a 5/8-inch (16 mm) diameter drilled hole with a minimum embedment of 4-1/2 inches (114 mm).

A minimum footing thickness of 8 inches (203 mm) is required and the minimum distance from each anchor to the edge of the footing shall be 3-3/4 inches (95 mm). The anchoring adhesive and anchors shall be installed in accordance with the manufacturer's instructions and have a minimum tensile capacity of 5,000 lbs. (22 kN). The bond beam reinforcement and attachment of braced wall panels to the stem wall shall be as shown in Figure R602.10.9.

53. 56. Replace Section R602.12, including all subsections, with the following:

R602.12 Practical wall bracing. All buildings in Seismic Design Categories A and B and detached buildings in Seismic Design Category C shall be permitted to be braced in accordance with this section as an alternative to the requirements of Section R602.10. Where a building, or portion thereof, does not comply with one or more of the bracing requirements in this section, those portions shall be designed and constructed in accordance with Section R301.1. The use of other bracing provisions of Section R602.10, except as specified herein, shall not be permitted.

The building official shall be permitted to require the permit applicant to identify bracing on the construction documents and provide associated analysis. The building official shall be permitted to waive the analysis of the upper floors where the cumulative length of wall openings of each upper floor wall is less than or equal to the length of the openings of the wall directly below.

R602.12.1 Sheathing materials. The following materials shall be permitted for use as sheathing for wall bracing. Exterior walls shall be sheathed on all sheathable surfaces, including infill areas between bracing locations, above and below wall openings, and on gable end walls.

1. Wood structural panels with a minimum thickness of 7/16 inch (9.5 mm) fastened in accordance with Table R602.3(3).

2. Structural fiberboard sheathing with a minimum thickness of 1/2 inch (12.7 mm) fastened in accordance with Table R602.3(1).

3. Gypsum board with a minimum thickness of 1/2 inch (12.7 mm) fastened in accordance with Table R702.3.5 on interior walls only.

R602.12.2 Braced wall panels. Braced wall panels shall be full-height wall sections sheathed with the materials listed in Section R602.12.1 and complying with the following:

1. Exterior braced wall panels shall have a minimum length based on the height of the adjacent opening as specified in Table R602.12.2. Panels with openings on both sides of differing heights shall be governed by the taller opening when determining panel length.

2. Interior braced wall panels shall have a minimum length of 48 inches (1220 mm) when sheathing material is applied to one side. Doubled-sided applications shall be permitted to be considered two braced wall panels.

3. Braced wall panels shall be permitted to be constructed of Methods ABW, PFH, PFG, and CS-PF in accordance with Section R602.10.4.

4. Exterior braced wall panels, other than the methods listed in Item 3 above shall have a finish material installed on the interior. The finish material shall consist of 1/2 inch (12.7 mm) gypsum board or equivalent and shall be permitted to be omitted where the required length of bracing, as determined in Section R602.12.4, is multiplied by 1.40, unless otherwise required by Section R302.6.

5. Vertical sheathing joints shall occur over and be fastened to common studs.

6. Horizontal sheathing joints shall be edge nailed to 1‑1/2 inch (38 mm) minimum thick common blocking.

Table R602.12.2

Braced Wall Panel Lengths | |

Location | Wall Height (feet) | |

|

8 | 9 | 10 | 11 | 12 | |

Minimum Panel Length (inches) | |

Adjacent garage door of one-story garagea | 24 | 27 | 30 | 33 | 36 | |

Adjacent all other openingsb | | | | | | |

Clear opening height (inches) ≤ 64 | 24 | 27 | 30 | 33 | 36 | |

Clear opening height (inches) ≤ 72 | 27 | 27 | 30 | 33 | 36 | |

Clear opening height (inches) ≤ 80 | 30 | 30 | 30 | 33 | 36 | |

Clear opening height (inches) > 80 | 36 | 36 | 36 | 40 | 40 | |

For SI: 1 inch = 25.4 mm, 1 foot = 304.8 mm. a. Braced wall panels supporting a gable end wall or roof load only. b. Interpolation shall be permitted. | |

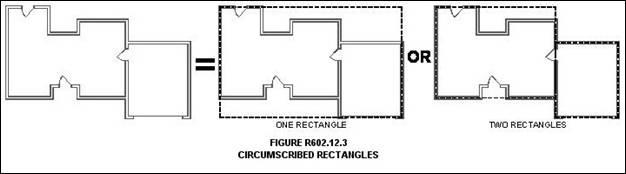

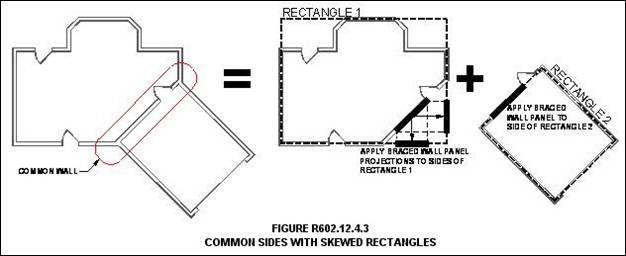

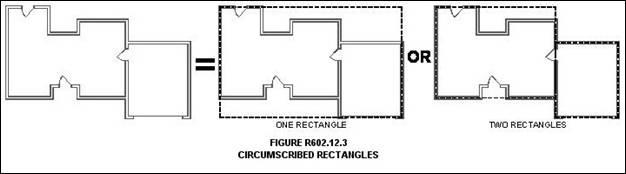

R602.12.3 Circumscribed rectangle. Required length of bracing shall be determined by circumscribing one or more rectangles around the entire building or portions thereof as shown in Figure R602.12.3. Rectangles shall surround all enclosed offsets and projections such as sunrooms and attached garages. Chimneys, partial height projections, and open structures, such as carports and decks, shall be excluded from the rectangle. Each rectangle shall have no side greater than 80 feet (24 384 (24,384 mm) with a maximum 3:1 ratio between the long and short side. Rectangles shall be permitted to be skewed to accommodate angled projections as shown in Figure R602.12.4.3.

R602.12.4 Required length of bracing. The required length of bracing for each side of a circumscribed rectangle shall be determined using Table R602.12.4. Where multiple rectangles share a common side or sides, the required length of bracing shall equal the sum of the required lengths from all shared rectangle sides.

Table R602.12.4

Required Length of Bracing Along Each Side of a Circumscribed Rectanglea,b,c |

Wind Speed | Eave-to-Ridge Height (feet) | Number of Floor Levels Abovee,f | Required Length of Bracing on Front/Rear Side (feet) | Required Length of Bracing on Left/Right Side (feet) |

Length of Left/Right Side (feet) | Length of Front/Rear Side (feet) |

10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 |

115 | 10 | 0 | 2.0 | 3.5 | 5.0 | 6.0 | 7.5 | 9.0 | 10.5 | 12.0 | 2.0 | 3.5 | 5.0 | 6.0 | 7.5 | 9.0 | 10.5 | 12.0 |

1d | 3.5 | 6.5 | 9.0 | 12.0 | 14.5 | 17.0 | 19.8 | 22.6 | 3.5 | 6.5 | 9.0 | 12.0 | 14.5 | 17.0 | 19.8 | 22.6 |

2d | 5.0 | 9.5 | 13.5 | 17.5 | 21.5 | 25.0 | 29.2 | 33.4 | 5.0 | 9.5 | 13.5 | 17.5 | 21.5 | 25.0 | 29.2 | 33.4 |

15 | 0 | 2.6 | 4.6 | 6.5 | 7.8 | 9.8 | 11.7 | 13.7 | 15.7 | 2.6 | 4.6 | 6.5 | 7.8 | 9.8 | 11.7 | 13.7 | 15.7 |

1d | 4.0 | 7.5 | 10.4 | 13.8 | 16.7 | 19.6 | 22.9 | 26.2 | 4.0 | 7.5 | 10.4 | 13.8 | 16.7 | 19.6 | 22.9 | 26.2 |

2d | 5.5 | 10.5 | 14.9 | 19.3 | 23.7 | 27.5 | 32.1 | 36.7 | 5.5 | 10.5 | 14.9 | 19.3 | 23.7 | 27.5 | 32.1 | 36.7 |

20 | 0 | 2.9 | 5.2 | 7.3 | 8.8 | 11.1 | 13.2 | 15.4 | 17.6 | 2.9 | 5.2 | 7.3 | 8.8 | 11.1 | 13.2 | 15.4 | 17.6 |

1d | 4.5 | 8.5 | 11.8 | 15.6 | 18.9 | 22.1 | 25.8 | 29.5 | 4.5 | 8.5 | 11.8 | 15.6 | 18.9 | 22.1 | 25.8 | 29.5 |

2d | 6.2 | 11.9 | 16.8 | 21.8 | 27.3 | 31.1 | 36.3 | 41.5 | 6.2 | 11.9 | 16.8 | 21.8 | 27.3 | 31.1 | 36.3 | 41.5 |

130 | 10 | 0 | 2.5 | 4.0 | 6.0 | 7.5 | 9.5 | 11.0 | 12.8 | 14.6 | 2.5 | 4.0 | 6.0 | 7.5 | 9.5 | 11.0 | 12.8 | 14.6 |

1d | 4.5 | 8.0 | 11.0 | 14.5 | 18.0 | 21.0 | 24.5 | 28.0 | 4.5 | 8.0 | 11.0 | 14.5 | 18.0 | 21.0 | 24.5 | 28.0 |

2d | 6.0 | 11.5 | 16.5 | 21.5 | 26.5 | 31.0 | 36.2 | 41.4 | 6.0 | 11.5 | 16.5 | 21.5 | 26.5 | 31.0 | 36.2 | 41.4 |

15 | 0 | 3.4 | 5.2 | 7.8 | 9.8 | 12.4 | 14.3 | 16.7 | 19.1 | 3.4 | 5.2 | 7.8 | 9.8 | 12.4 | 14.3 | 16.7 | 19.1 |

1d | 5.2 | 9.2 | 12.7 | 16.7 | 20.7 | 24.2 | 28.2 | 32.2 | 5.2 | 9.2 | 12.7 | 16.7 | 20.7 | 24.2 | 28.2 | 32.2 |

2d | 6.6 | 12.7 | 18.2 | 23.7 | 29.2 | 34.1 | 39.8 | 45.5 | 6.6 | 12.7 | 18.2 | 23.7 | 29.2 | 34.1 | 39.8 | 45.5 |

20 | 0 | 3.8 | 5.9 | 8.8 | 11.1 | 14.0 | 16.2 | 18.9 | 21.6 | 3.8 | 5.9 | 8.8 | 11.1 | 14.0 | 16.2 | 18.9 | 21.6 |

1d | 5.9 | 10.4 | 14.4 | 18.9 | 23.4 | 27.3 | 31.8 | 36.3 | 5.9 | 10.4 | 14.4 | 18.9 | 23.4 | 27.3 | 31.8 | 36.3 |

2d | 7.5 | 14.4 | 20.6 | 26.8 | 33.0 | 38.5 | 44.9 | 51.3 | 7.5 | 14.4 | 20.6 | 26.8 | 33.0 | 38.5 | 44.9 | 51.3 |

For SI: 1 ft = 304.8 mm. a. Interpolation shall be permitted; extrapolation shall be prohibited. b. For Exposure Category C, multiply the required length of bracing by a factor of 1.20 for a one-story building, 1.30 for a two-story building, and 1.40 for a three-story building. c. For wall height adjustments multiply the required length of bracing by the following factors: 0.90 for 8 feet (2438 mm), 0.95 for 9 feet (2743 mm), 1.0 for 10 feet (3048 mm), 1.05 for 11 feet (3353 mm), and 1.10 for 12 feet (3658 mm). d. Where braced wall panels supporting stories above have been sheathed in wood structural panels with edge fasteners spaced at 4 inches (102 mm) on center, multiply the required length of bracing by 0.83. e. A floor level, habitable or otherwise, contained wholly within the roof rafters or trusses shall not be considered a floor level for purposes of determining the required length of bracing. f. A rectangle side with differing number of floor levels above shall use the greatest number when determining the required length of bracing. |

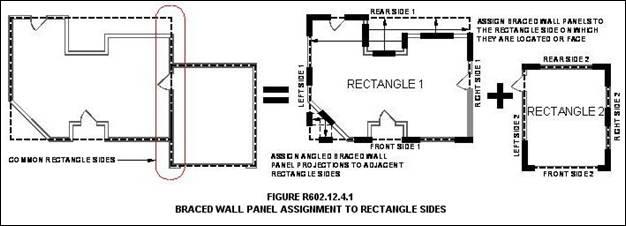

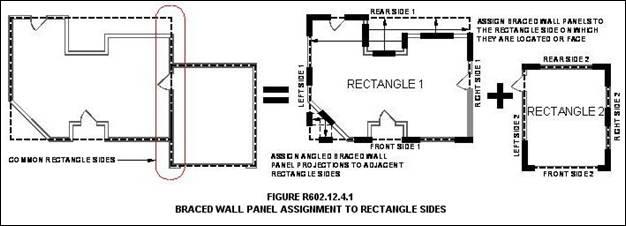

R602.12.4.1 Braced wall panel assignment to rectangle sides. Braced wall panels shall be assigned to the applicable rectangle side and contribute to its required length of bracing. Panels shall be assigned as specified below and as shown in Figure R602.12.4.1.

1. Exterior braced wall panels shall be assigned to the parallel rectangle side on which they are located or in which they face.

2. Interior braced wall panels shall be assigned to the parallel rectangle side on which they are located or in which they face up to 4 feet (1220 mm) away. Interior braced wall panels more than 4 feet (1220 mm) away from a parallel rectangle side shall not contribute.

3. The projections of angled braced wall panels shall be assigned to the adjacent rectangle sides.

R602.12.4.2 Contributing length. The cumulative contributing length of braced wall panels assigned to a rectangle side shall be greater than or equal to the required length of bracing as determined in Section R602.12.4. The contributing length of a braced wall panel shall be as specified below. When applying contributing length to angled braced wall panels, apply the requirements below to each projection:

1. Exterior braced wall panels shall contribute their actual length.

2. Interior braced wall panels shall contribute one-half of their actual length.

3. The contributing length of Methods ABW, PFH, PFG, and CS-PF shall be in accordance with Table R602.10.5.

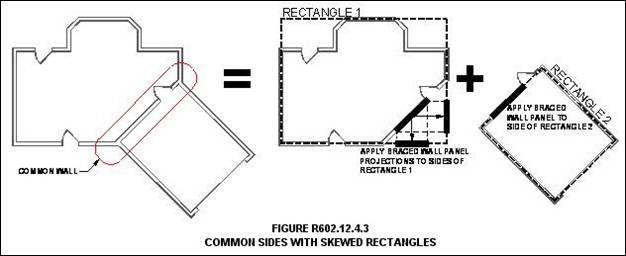

R602.12.4.3 Common sides with skewed rectangles. Braced wall panels located on a common wall where skewed rectangles intersect, as shown in Figure R602.12.4.3, shall be permitted to be assigned to the parallel rectangle side, and their projections shall be permitted to be assigned to the adjacent skewed rectangle sides.

R602.12.5 Cripple walls and framed walls of walk-out basements. For rectangle sides with cripple walls having a maximum height of 48 inches (1220 mm), the required length of bracing shall be as determined in Section R602.12.4. For rectangle sides with cripple walls having a height greater than 48 inches (1220 mm) at any location or framed walls of a walk-out basement, the required length of bracing shall be determined using Table R602.12.4. Braced wall panels within cripple walls and walls of walk-out basements shall comply with Item 4 of Section R602.12.2.

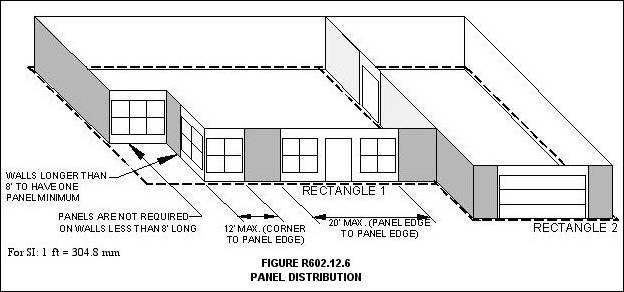

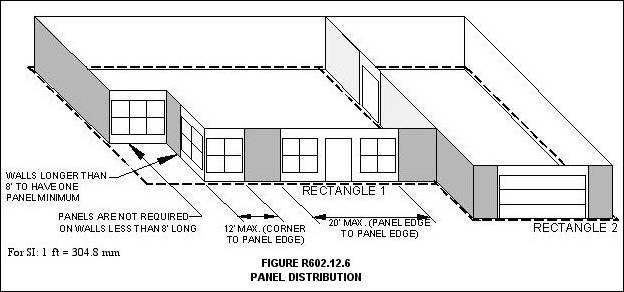

R602.12.6 Distribution of braced wall panels. Braced wall panels shall be distributed in accordance with the following requirements as shown in Figure R602.12.6.

1. The edge of a braced wall panel shall be no more than 12 feet (3658 mm) from any building corner or rectangle corner.

2. The distance between adjacent edges of braced wall panels shall be no more than 20 feet (6096 mm).

3. Segments of exterior walls greater than 8 feet (2438 mm) in length shall have a minimum of one braced wall panel.

4. Segments of exterior wall 8 feet (2438 mm) or less in length shall be permitted to have no braced wall panels.

R602.12.4 Required length of bracing. The required length of bracing for each side of a circumscribed rectangle shall be determined using Table R602.12.4. Where multiple rectangles share a common side or sides, the required length of bracing shall equal the sum of the required lengths from all shared rectangle sides.

Table R602.12.4

Required Length of Bracing Along Each Side of a Circumscribed Rectanglea,b,c |

Wind Speed | Eave-to-Ridge Height (feet) | Number of Floor Levels Abovee,f | Required Length of Bracing on Front/Rear Side (feet) | Required Length of Bracing on Left/Right Side (feet) |

Length of Left/Right Side (feet) | Length of Front/Rear Side (feet) |

10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 |

115 | 10 | 0 | 2.0 | 3.5 | 5.0 | 6.0 | 7.5 | 9.0 | 10.5 | 12.0 | 2.0 | 3.5 | 5.0 | 6.0 | 7.5 | 9.0 | 10.5 | 12.0 |

1d | 3.5 | 6.5 | 9.0 | 12.0 | 14.5 | 17.0 | 19.8 | 22.6 | 3.5 | 6.5 | 9.0 | 12.0 | 14.5 | 17.0 | 19.8 | 22.6 |

2d | 5.0 | 9.5 | 13.5 | 17.5 | 21.5 | 25.0 | 29.2 | 33.4 | 5.0 | 9.5 | 13.5 | 17.5 | 21.5 | 25.0 | 29.2 | 33.4 |

15 | 0 | 2.6 | 4.6 | 6.5 | 7.8 | 9.8 | 11.7 | 13.7 | 15.7 | 2.6 | 4.6 | 6.5 | 7.8 | 9.8 | 11.7 | 13.7 | 15.7 |

1d | 4.0 | 7.5 | 10.4 | 13.8 | 16.7 | 19.6 | 22.9 | 26.2 | 4.0 | 7.5 | 10.4 | 13.8 | 16.7 | 19.6 | 22.9 | 26.2 |

2d | 5.5 | 10.5 | 14.9 | 19.3 | 23.7 | 27.5 | 32.1 | 36.7 | 5.5 | 10.5 | 14.9 | 19.3 | 23.7 | 27.5 | 32.1 | 36.7 |

20 | 0 | 2.9 | 5.2 | 7.3 | 8.8 | 11.1 | 13.2 | 15.4 | 17.6 | 2.9 | 5.2 | 7.3 | 8.8 | 11.1 | 13.2 | 15.4 | 17.6 |

1d | 4.5 | 8.5 | 11.8 | 15.6 | 18.9 | 22.1 | 25.8 | 29.5 | 4.5 | 8.5 | 11.8 | 15.6 | 18.9 | 22.1 | 25.8 | 29.5 |

2d | 6.2 | 11.9 | 16.8 | 21.8 | 27.3 | 31.1 | 36.3 | 41.5 | 6.2 | 11.9 | 16.8 | 21.8 | 27.3 | 31.1 | 36.3 | 41.5 |

130 | 10 | 0 | 2.5 | 4.0 | 6.0 | 7.5 | 9.5 | 11.0 | 12.8 | 14.6 | 2.5 | 4.0 | 6.0 | 7.5 | 9.5 | 11.0 | 12.8 | 14.6 |

1d | 4.5 | 8.0 | 11.0 | 14.5 | 18.0 | 21.0 | 24.5 | 28.0 | 4.5 | 8.0 | 11.0 | 14.5 | 18.0 | 21.0 | 24.5 | 28.0 |

2d | 6.0 | 11.5 | 16.5 | 21.5 | 26.5 | 31.0 | 36.2 | 41.4 | 6.0 | 11.5 | 16.5 | 21.5 | 26.5 | 31.0 | 36.2 | 41.4 |

15 | 0 | 3.4 | 5.2 | 7.8 | 9.8 | 12.4 | 14.3 | 16.7 | 19.1 | 3.4 | 5.2 | 7.8 | 9.8 | 12.4 | 14.3 | 16.7 | 19.1 |

1d | 5.2 | 9.2 | 12.7 | 16.7 | 20.7 | 24.2 | 28.2 | 32.2 | 5.2 | 9.2 | 12.7 | 16.7 | 20.7 | 24.2 | 28.2 | 32.2 |

2d | 6.6 | 12.7 | 18.2 | 23.7 | 29.2 | 34.1 | 39.8 | 45.5 | 6.6 | 12.7 | 18.2 | 23.7 | 29.2 | 34.1 | 39.8 | 45.5 |

20 | 0 | 3.8 | 5.9 | 8.8 | 11.1 | 14.0 | 16.2 | 18.9 | 21.6 | 3.8 | 5.9 | 8.8 | 11.1 | 14.0 | 16.2 | 18.9 | 21.6 |

1d | 5.9 | 10.4 | 14.4 | 18.9 | 23.4 | 27.3 | 31.8 | 36.3 | 5.9 | 10.4 | 14.4 | 18.9 | 23.4 | 27.3 | 31.8 | 36.3 |

2d | 7.5 | 14.4 | 20.6 | 26.8 | 33.0 | 38.5 | 44.9 | 51.3 | 7.5 | 14.4 | 20.6 | 26.8 | 33.0 | 38.5 | 44.9 | 51.3 |

For SI: 1 ft = 304.8 mm. a. Interpolation shall be permitted; extrapolation shall be prohibited. b. For Exposure Category C, multiply the required length of bracing by a factor of 1.20 for a one-story building, 1.30 for a two-story building, and 1.40 for a three-story building. c. For wall height adjustments multiply the required length of bracing by the following factors: 0.90 for 8 feet (2438 mm), 0.95 for 9 feet (2743 mm), 1.0 for 10 feet (3048 mm), 1.05 for 11 feet (3353 mm), and 1.10 for 12 feet (3658 mm). d. Where braced wall panels supporting stories above have been sheathed in wood structural panels with edge fasteners spaced at 4 inches (102 mm) on center, multiply the required length of bracing by 0.83. e. A floor level, habitable or otherwise, contained wholly within the roof rafters or trusses shall not be considered a floor level for purposes of determining the required length of bracing. f. A rectangle side with differing number of floor levels above shall use the greatest number when determining the required length of bracing. |

R602.12.4.1 Braced wall panel assignment to rectangle sides. Braced wall panels shall be assigned to the applicable rectangle side and contribute to its required length of bracing. Panels shall be assigned as specified below and as shown in Figure R602.12.4.1.

1. Exterior braced wall panels shall be assigned to the parallel rectangle side on which they are located or in which they face.

2. Interior braced wall panels shall be assigned to the parallel rectangle side on which they are located or in which they face up to 4 feet (1220 mm) away. Interior braced wall panels more than 4 feet (1220 mm) away from a parallel rectangle side shall not contribute.

3. The projections of angled braced wall panels shall be assigned to the adjacent rectangle sides.

R602.12.4.2 Contributing length. The cumulative contributing length of braced wall panels assigned to a rectangle side shall be greater than or equal to the required length of bracing as determined in Section R602.12.4. The contributing length of a braced wall panel shall be as specified below. When applying contributing length to angled braced wall panels, apply the requirements below to each projection:

1. Exterior braced wall panels shall contribute their actual length.

2. Interior braced wall panels shall contribute one-half of their actual length.

3. The contributing length of Methods ABW, PFH, PFG, and CS-PF shall be in accordance with Table R602.10.5.

R602.12.4.3 Common sides with skewed rectangles. Braced wall panels located on a common wall where skewed rectangles intersect, as shown in Figure R602.12.4.3, shall be permitted to be assigned to the parallel rectangle side, and their projections shall be permitted to be assigned to the adjacent skewed rectangle sides.

R602.12.5 Cripple walls and framed walls of walk-out basements. For rectangle sides with cripple walls having a maximum height of 48 inches (1220 mm), the required length of bracing shall be as determined in Section R602.12.4. For rectangle sides with cripple walls having a height greater than 48 inches (1220 mm) at any location or framed walls of a walk-out basement, the required length of bracing shall be determined using Table R602.12.4. Braced wall panels within cripple walls and walls of walk-out basements shall comply with Item 4 of Section R602.12.2.

R602.12.6 Distribution of braced wall panels. Braced wall panels shall be distributed in accordance with the following requirements as shown in Figure R602.12.6.

1. The edge of a braced wall panel shall be no more than 12 feet (3658 mm) from any building corner or rectangle corner.

2. The distance between adjacent edges of braced wall panels shall be no more than 20 feet (6096 mm).

3. Segments of exterior walls greater than 8 feet (2438 mm) in length shall have a minimum of one braced wall panel.

4. Segments of exterior wall 8 feet (2438 mm) or less in length shall be permitted to have no braced wall panels.

R602.12.6.1 Panels adjacent to balloon framed walls. Braced wall panels shall be placed on each side of each story adjacent to balloon framed walls designed in accordance with Section R602.3 with a maximum height of two stories.

R602.12.7 Braced wall panel connection. Braced wall panels shall be connected to other structural elements in accordance with Section R602.10.8.

R602.12.8 Braced wall panel support. Braced wall panels shall be supported in accordance with Section R602.10.9.

54. Change Sections R802.2 and R802.3 to read:

R802.2 Design and construction. The roof and ceiling assembly shall provide continuous ties across the structure to prevent roof thrust from being applied to the supporting walls. The assembly shall be designed and constructed in accordance with the provisions of this chapter and Figures R606.11(1), R606.11(2) and R606.11(3) or in accordance with AWC NDS.

R802.3 Ridge. A ridge board used to connect opposing rafters shall be not less than 1 inch (25 mm) nominal thickness and not less in depth than the cut end of the rafter. Where ceiling joist or rafter ties do not provide a continuous ties across the structure, a ridge beam shall be provided and supported on each end by a wall or girder.

55. Delete Sections R802.3.1, R802.3.2 and R802.3.3.

56. Change Section R802.4 and add Section R802.4.1 to read:

R802.4 Rafters. Rafters shall be in accordance with this section.

R802.4.1 Rafter size. Rafters shall be sized based on the rafter spans in Tables R802.4.1(1) through R802.4.1(8). Rafter spans shall be measured along the horizontal projection of the rafter. For other grades and species and for other loading conditions, refer to the AWC STJR.

57. Change the titles of Tables R802.4(1) and R802.4(2) to Tables R802.5.1(1) and R802.5.1(2), respectively, and change the titles of Tables R802.5.1(1) through R802.5.1(8) to Tables R802.4.1(1) through R802.4.1(8), respectively.

58. Add Sections R802.4.2 through R802.4.5 to read:

R802.4.2 Framing details. Rafters shall be framed not more than 1-1/2 inches (38 mm) offset from each other to a ridge board or directly opposite from each other with a collar tie, gusset plate or ridge strap in accordance with Table R602.3(1). Rafters shall be nailed to the top wall plates in accordance with Table R602.3(1) unless the roof assembly is required to comply with the uplift requirements of Section R802.11.

R802.4.3 Hips and valleys. Hip and valley rafters shall be not less than 2 inches (51 mm) nominal in thickness and not less in depth than the cut end of the rafter. Hip and valley rafters shall be supported at the ridge by a brace to a bearing partition or be designed to carry and distribute the specific load at that point.

R802.4.4 Rafter supports. Where the roof pitch is less than 3:12 (25% slope), structural members that support rafters, such as ridges, hips and valleys, shall be designed as beams, and bearing shall be provided for rafters in accordance with Section R802.6.

R802.4.5 Purlins. Installation of purlins to reduce the span of rafters is permitted as shown in Figure R802.4.5. Purlins shall be sized not less than the required size of the rafters that they support. Purlins shall be continuous and shall be supported by 2-inch by 4-inch (51 mm by 102 mm) braces installed to bearing walls at a slope not less than 45 degrees (0.79 rad) from the horizontal. The braces shall be spaced not more than 4 feet (1219 mm) on center and the unbraced length of braces shall not exceed 8 feet (2438 mm).

59. Add Figure R802.4.5 to read:

EDITOR'S NOTE: Figure R802.4.5, Brace Rafter Construction, is deleted; therefore the figure is not set out.

60. Add Section R802.4.6 to read:

R802.4.6 Collar ties. Where collar ties are used to connect opposing rafters, they shall be located in the upper third of the attic space and fastened in accordance with Table R602.3(1). Collar ties shall be not less than 1 inch by 4 inches (25 mm by 102 mm) nominal, spaced not more than 4 feet (1219 mm) on center. Ridge straps in accordance with Table R602.3(1) shall be permitted to replace collar ties.

61. Change Sections R802.5 and R802.5.1 to read:

R802.5 Ceiling joists. Ceiling joists shall be continuous across the structure or securely joined where they meet over interior partitions in accordance with Table R802.5.2.